The content displayed below is for educational and archival purposes only.

Unless stated otherwise, content is © Watch Tower Bible and Tract Society of Pennsylvania

You may be able to find the original on wol.jw.org

TABLE OF CONTENTS

DESCRIPTION PAGE

-

I. GENERAL CONSIDERATIONS

-

II. DESIGN DESCRIPTIONS

-

III. ARCHITECTURAL CONSIDERATIONS

-

IV. CIVIL CONSIDERATIONS

-

V. STRUCTURAL CONSIDERATIONS

-

VI. MECHANICAL SYSTEMS CONSIDERATIONS

-

VII. ELECTRICAL CONSIDERATIONS

-

VIII. APPENDICES

-

I. GENERAL CONSIDERATIONS

-

1. Cost and time efficiency can be maintained through familiarity and repetition of design. Architectural and engineering costs can also be controlled.

-

2. The quality of materials and general workmanship can be established and maintained with the enforcement of standard designs. A Kingdom Hall is a commercial building that is subject to a much greater amount of abuse than a residential structure, especially if multiple congregations use the building. A building of appropriate quality will serve the brothers well for many years and not become a maintenance problem.

-

3. The designs are based on design criteria and standards established by recognized professional organizations and industry standards along with input from many Regional Building Committees throughout the country. Use of these standard plans will minimize time-consuming debates regarding design and costly customization requests from the local building committees.

-

1. Level of skill in various trades, personnel and materials available vary greatly among regional groups throughout the country. Therefore, the local building committees should consider optional features included in the standard designs only if they are compatible with the abilities of the Regional Building Committee involved.

-

2. When selecting exterior finishes, thought needs to be given to what is appropriate and acceptable in the local community. This may affect colors, roof (finish, style and slope), wall finishes and use of windows.

-

3. Security requirements need to be determined locally. This will have an affect on the use of windows, additional exterior doors, a security system, exterior lighting and controlled access to the property.

-

1. All Kingdom Halls must be built in compliance with all applicable code requirements. This is the responsibility of the registered design professional.

-

2. The designs are in overall compliance with the Americans with Disabilities Act (ADA) and American National Standards Institute (ANSI) requirements for wheelchair accessibility. However, these requirements are subject to the local municipality’s interpretation and application.

-

3. The terminology used on these plans is for the purpose of identifying spaces and can be adjusted.

-

1. All drawings, designs and calculations must be signed and sealed by a registered design professional licensed as required by the state where the Kingdom Hall is to be constructed. These local professionals will be responsible and liable for the design, drawings, and calculations including conformance with all applicable codes and standards. Therefore, the intent of these “Standard Designs” is to provide general design guidelines to the registered design professional for his preparation of the construction documents.

-

2. These drawings should not be used in any way that could jeopardize the licensure of the registered design professional.

-

II. DESIGN DESCRIPTIONS

-

A. SINGLE KINGDOM HALLS

DESIGN NO. DESCRIPTION/COMMENTS

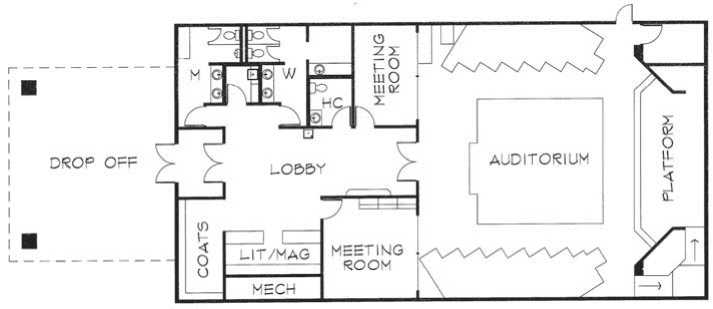

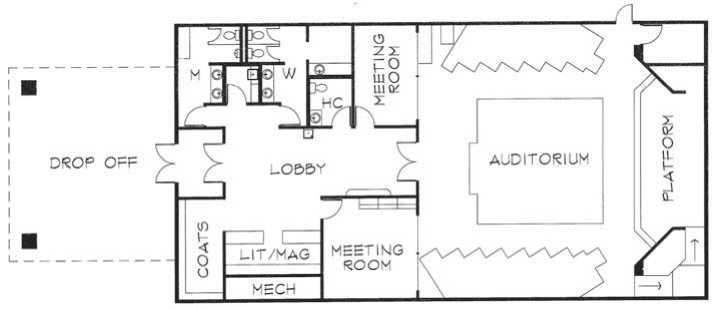

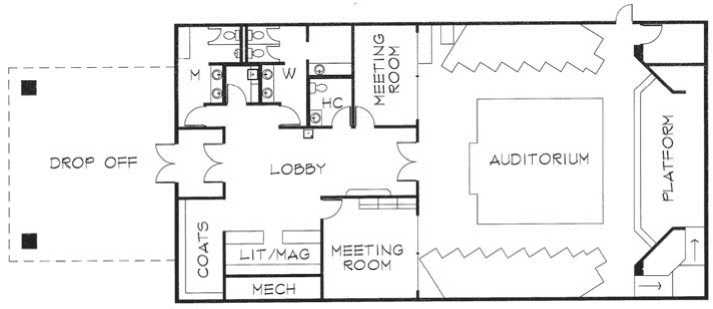

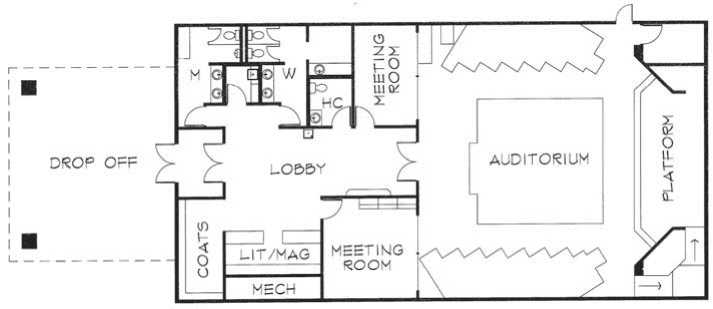

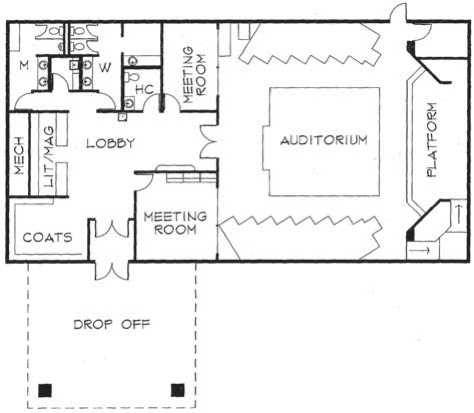

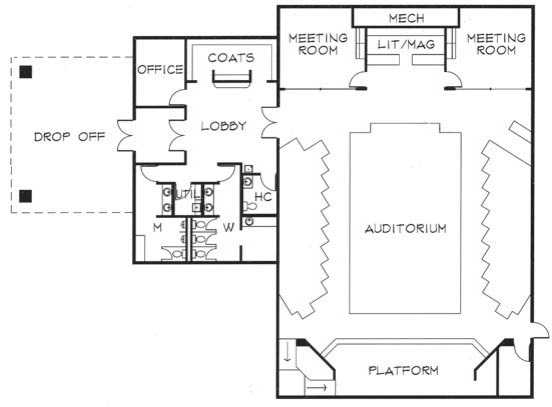

DESIGN 01 Rectangular floor plan with short end wall entry.

Auditorium seating for 130.

Recommended for small congregations.

This building can easily be lengthened a maximum of 10 feet to increase seating capacity to 185. It is recommended that doors be installed separating the auditorium from the lobby (if allowed by local codes) due to visibility of the entry door from the platform.

—

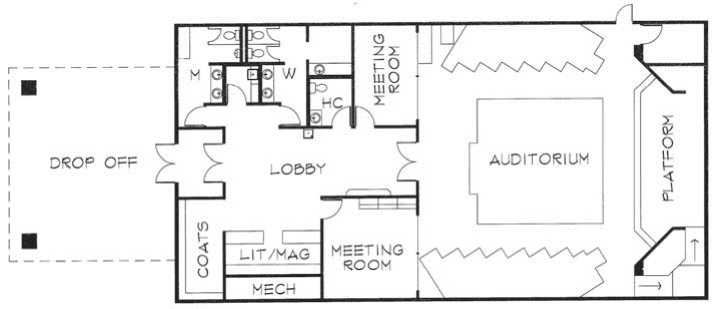

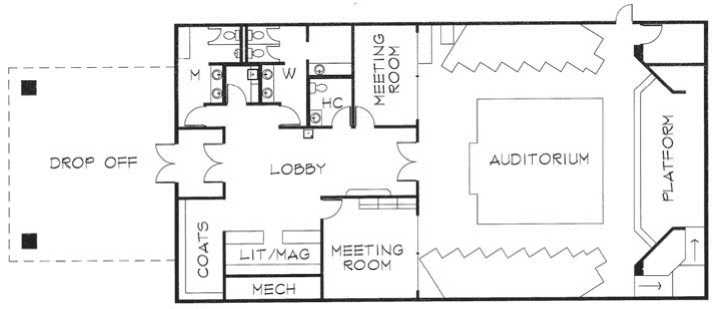

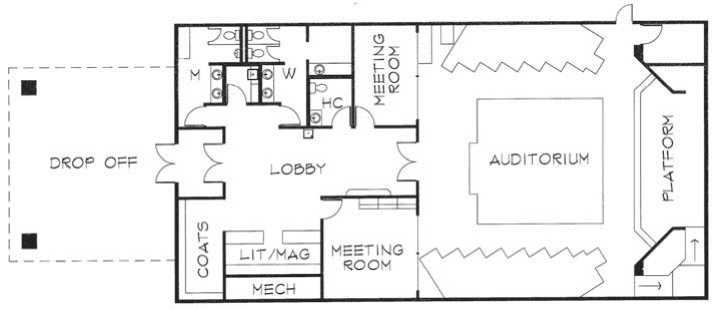

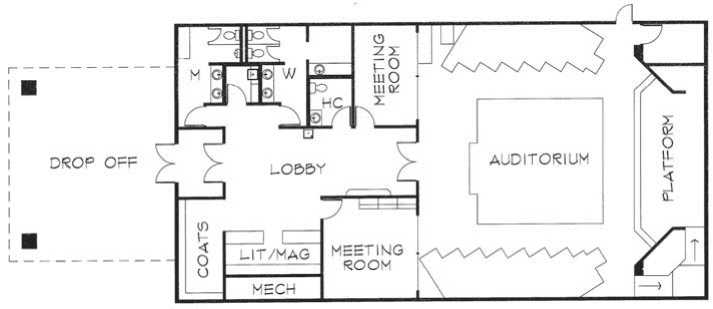

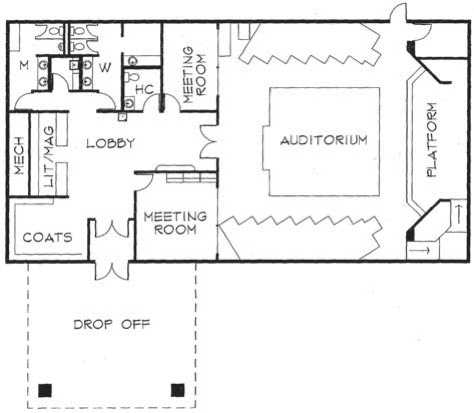

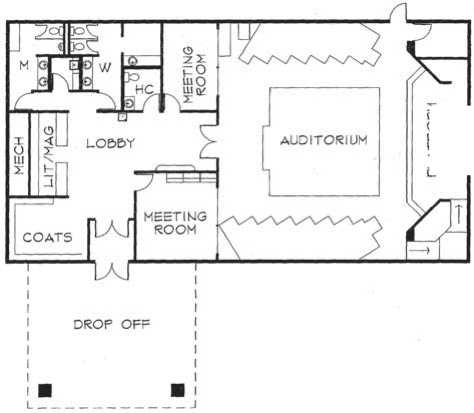

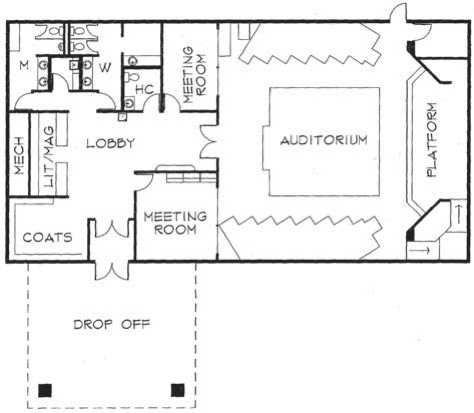

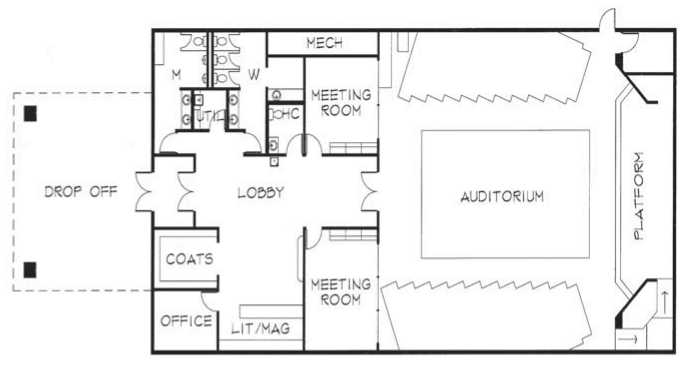

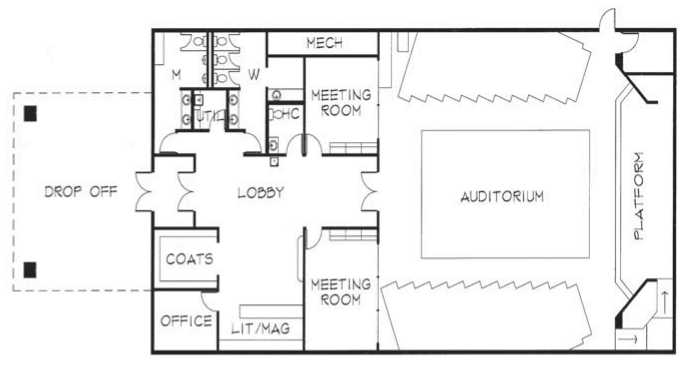

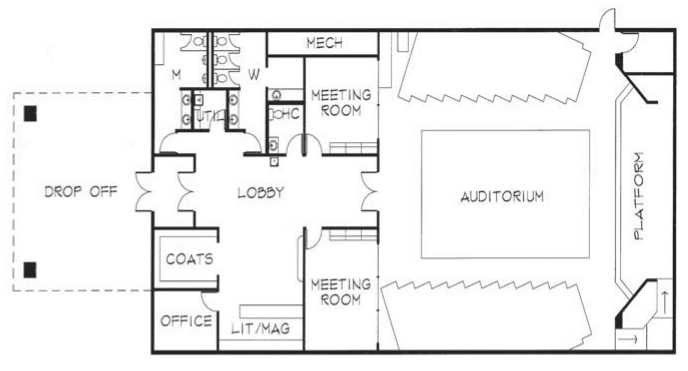

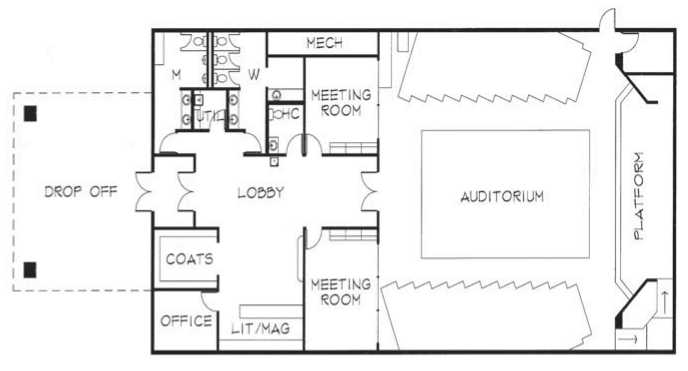

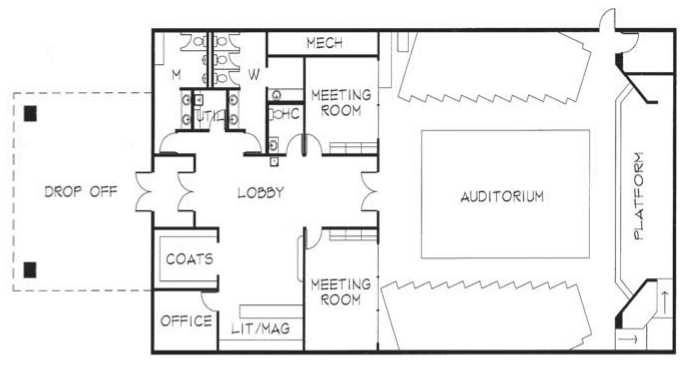

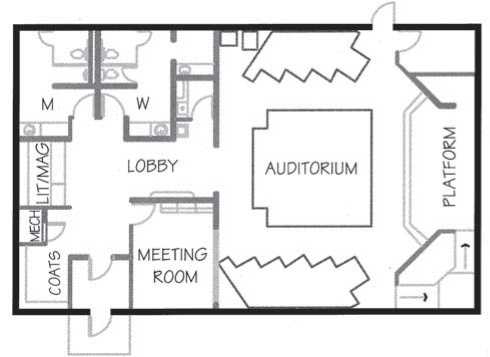

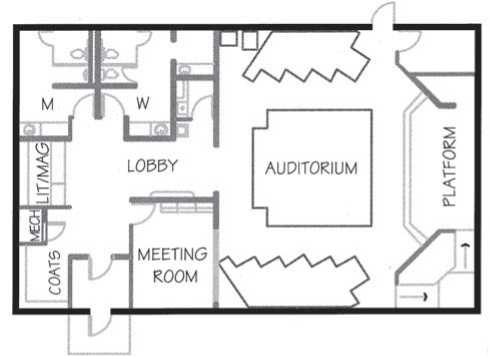

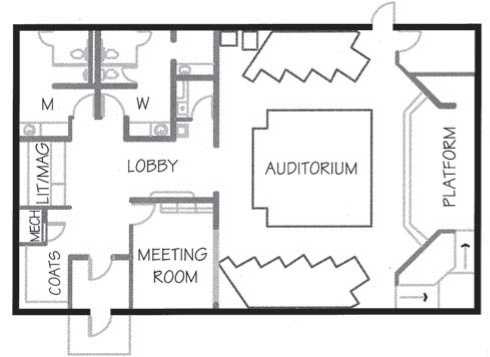

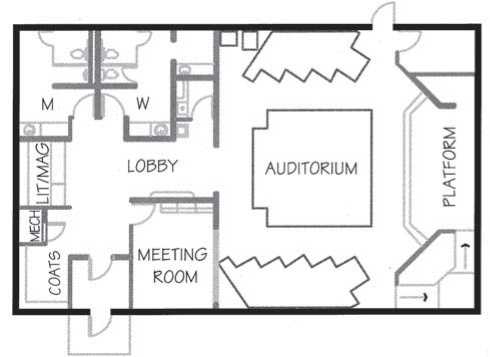

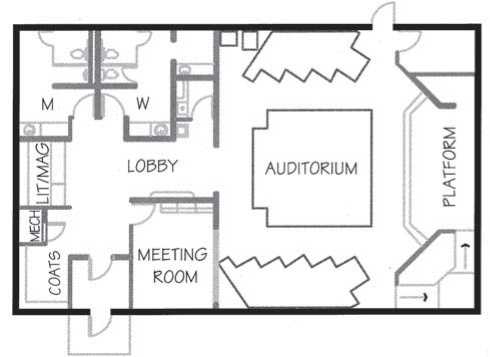

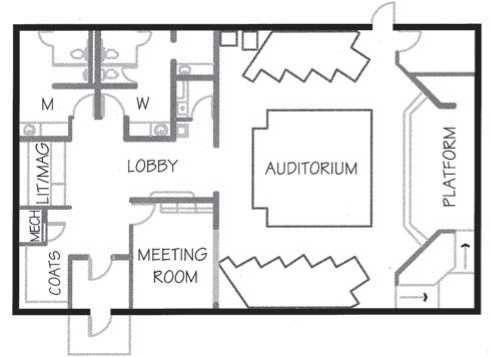

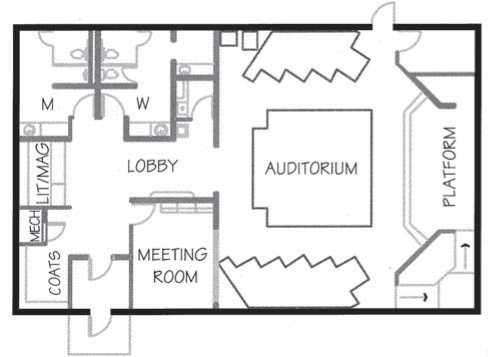

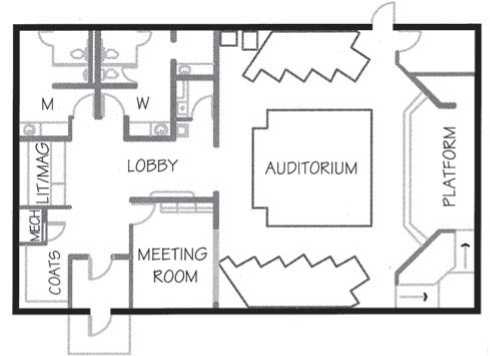

DESIGN 02 Rectangular floor plan with long side wall entry.

Auditorium seating for 130.

Recommended for small congregations.

This building can easily be lengthened a maximum of 10 feet to increase seating capacity to 185.

1

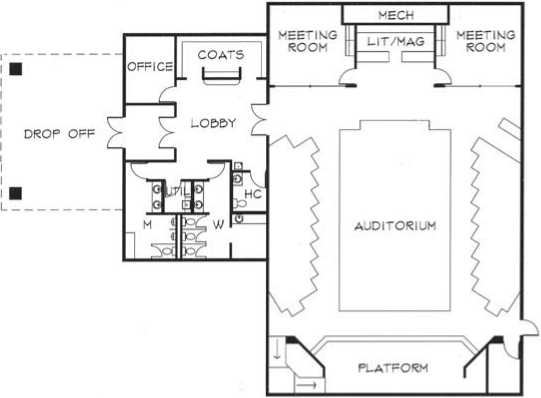

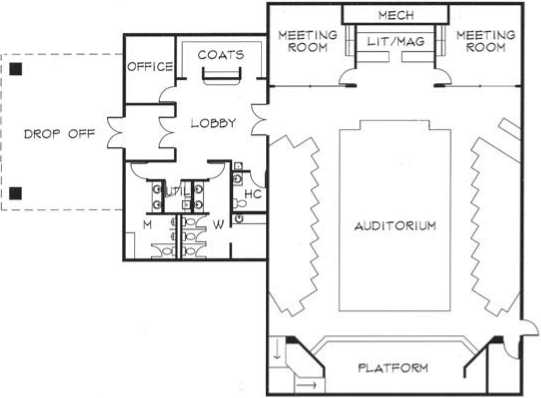

DESIGN 03 Rectangular floor plan with short end wall entry.

Auditorium seating for 225.

It is recommended that doors be installed separating the auditorium from the lobby (if allowed by local codes) due to visibility of the entry door from the platform.

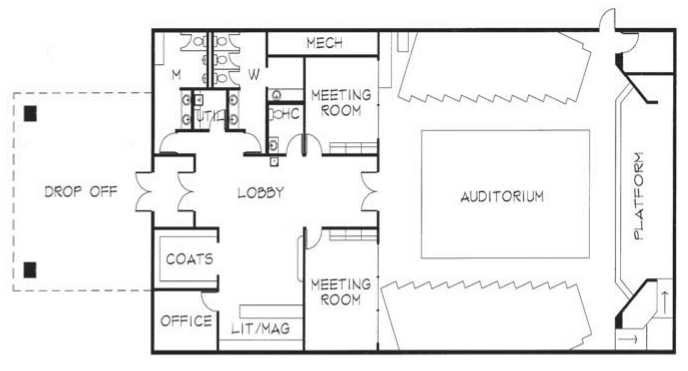

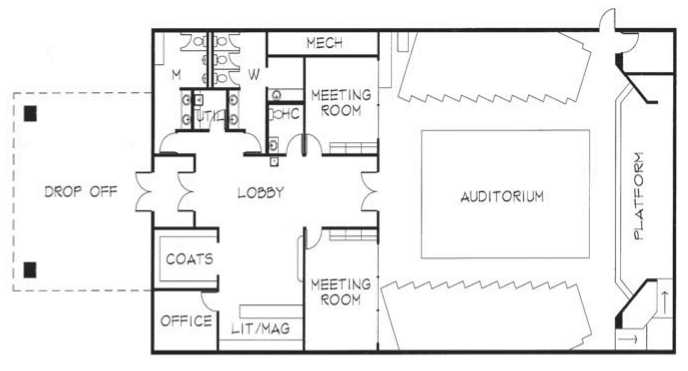

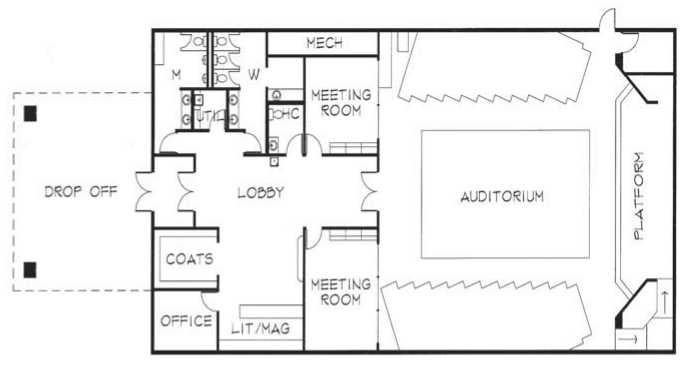

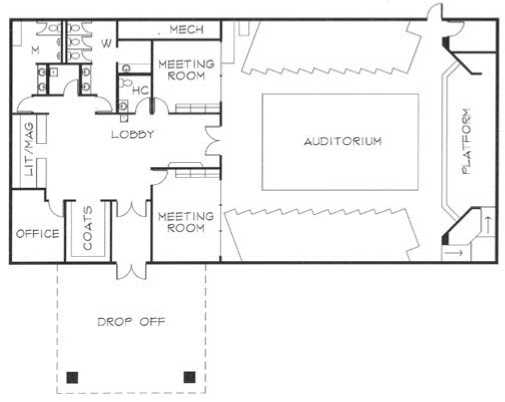

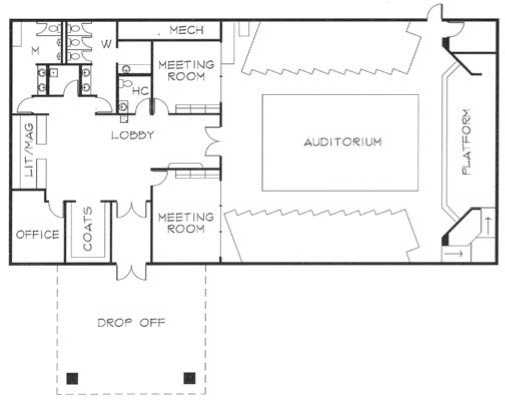

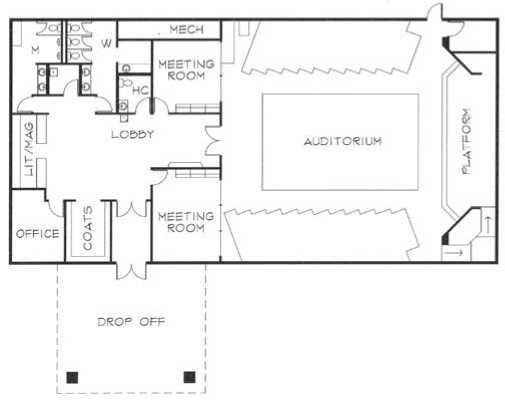

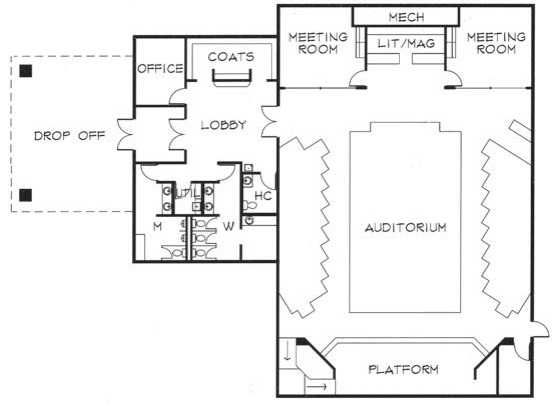

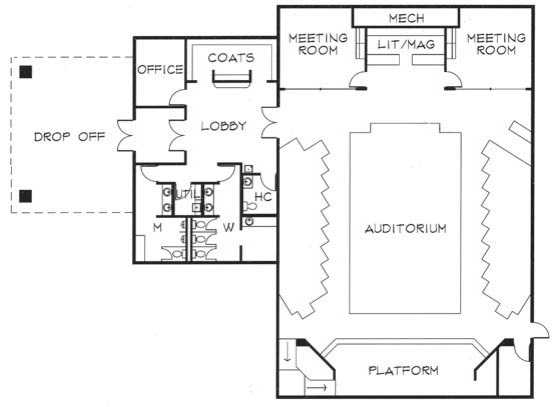

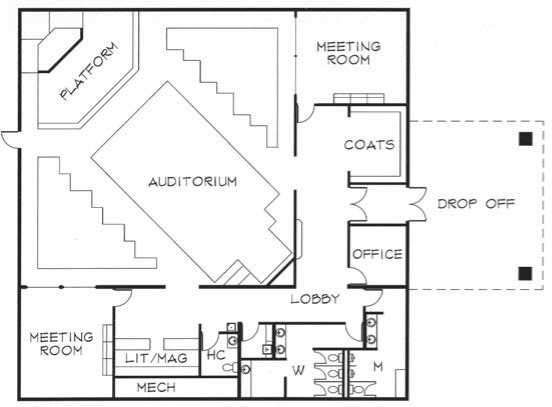

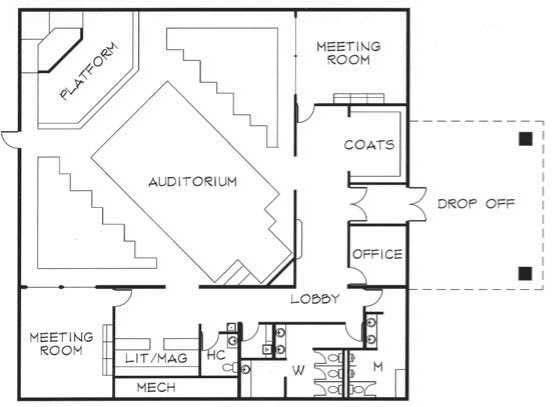

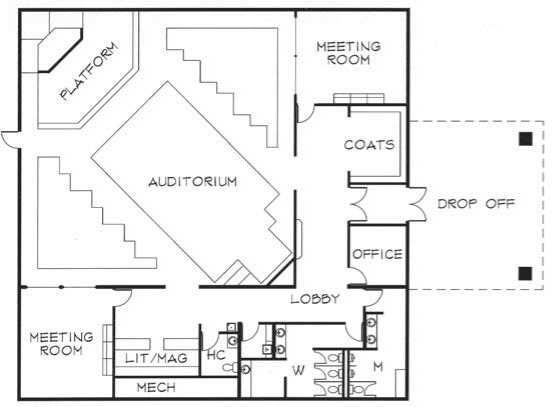

DESIGN 04 Rectangular floor plan with long side wall entry.

Auditorium seating for 225.

1

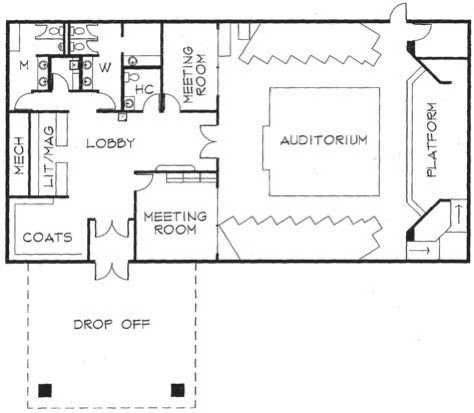

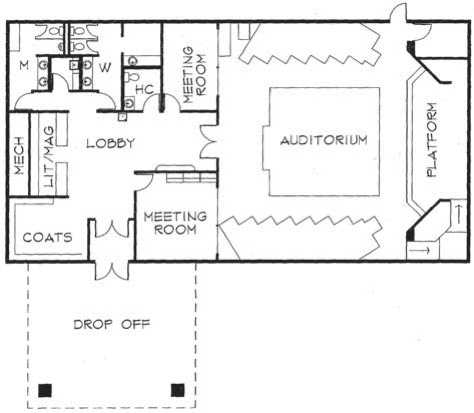

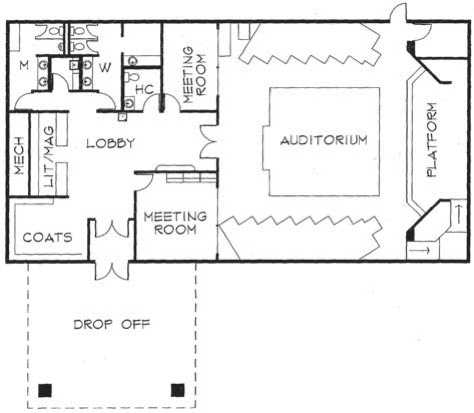

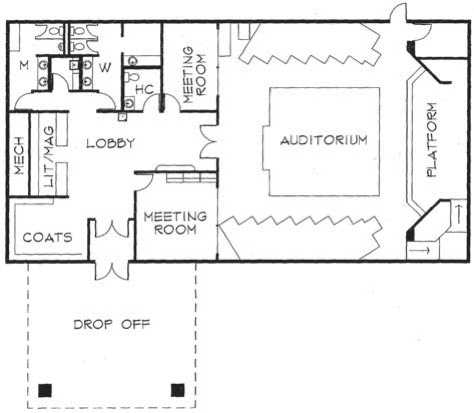

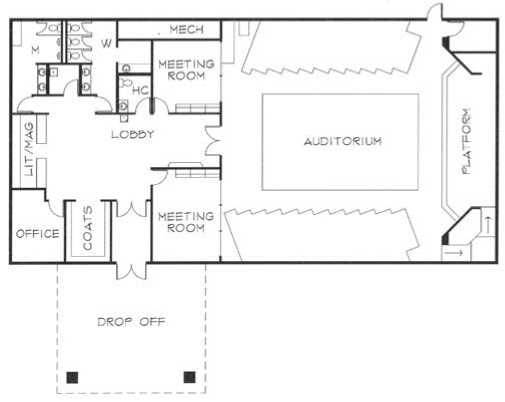

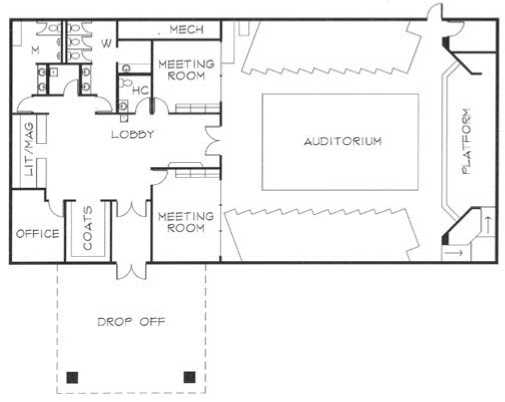

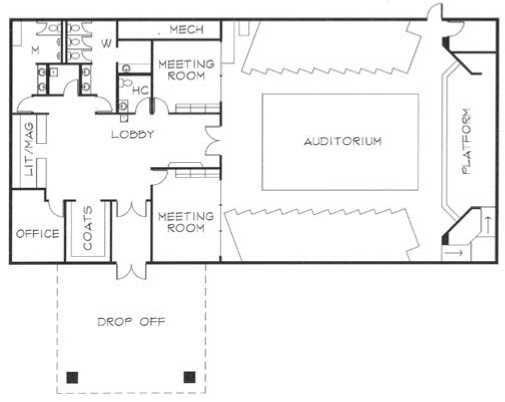

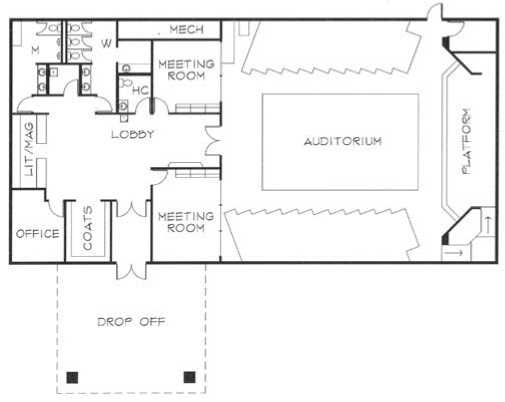

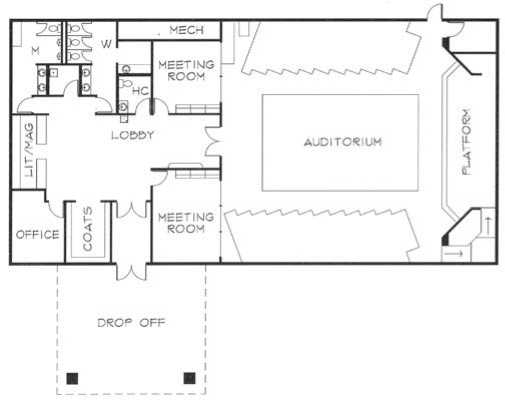

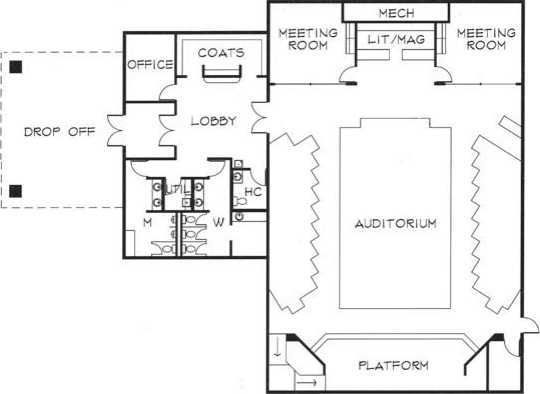

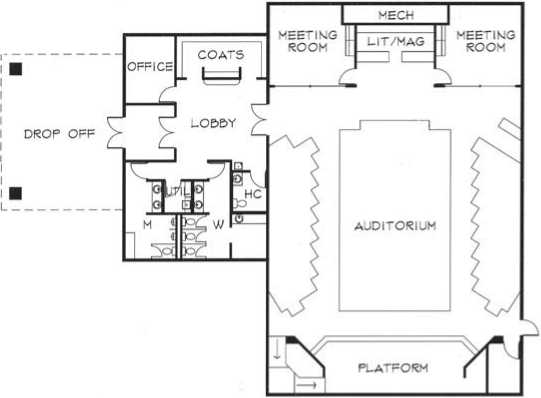

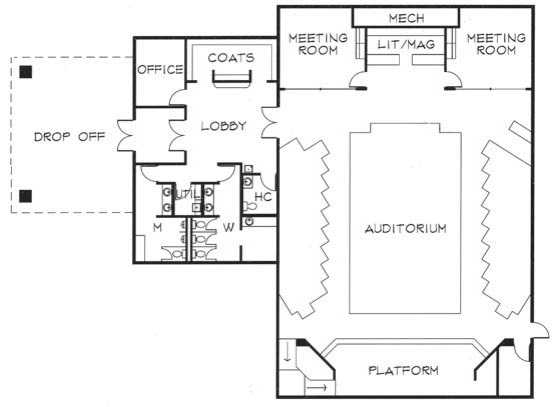

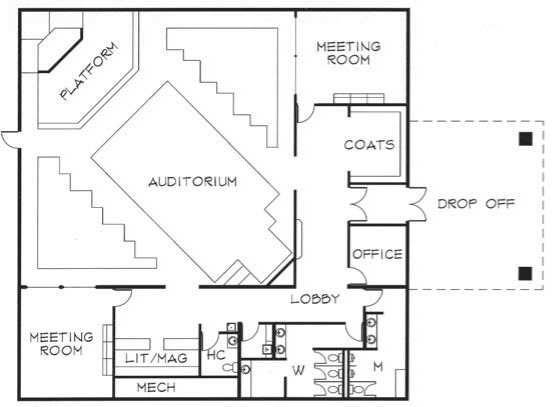

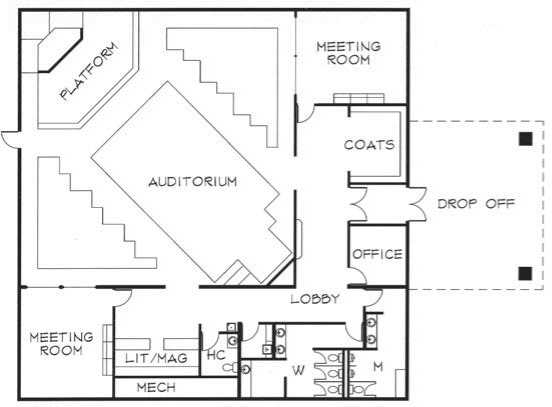

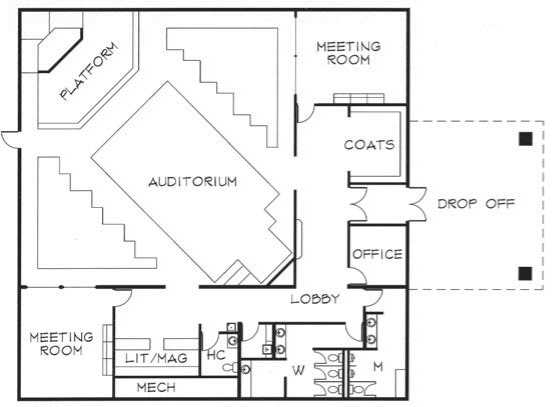

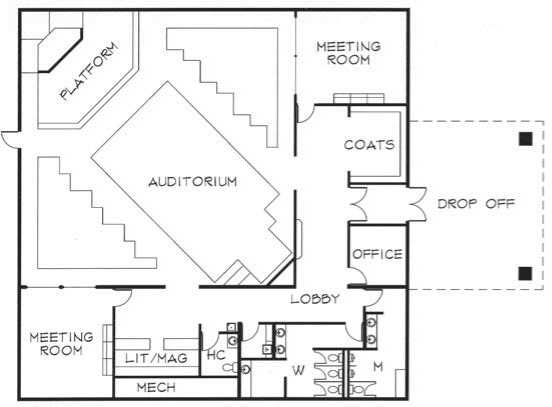

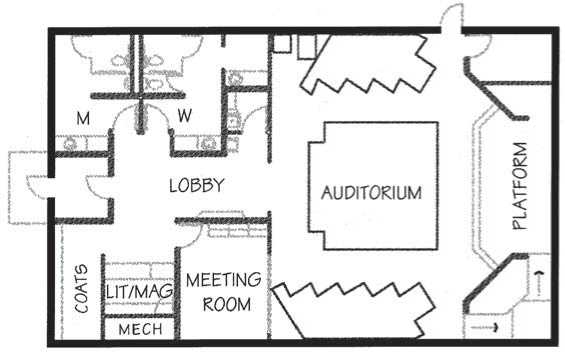

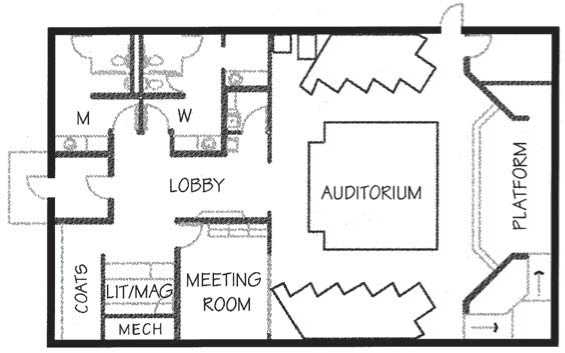

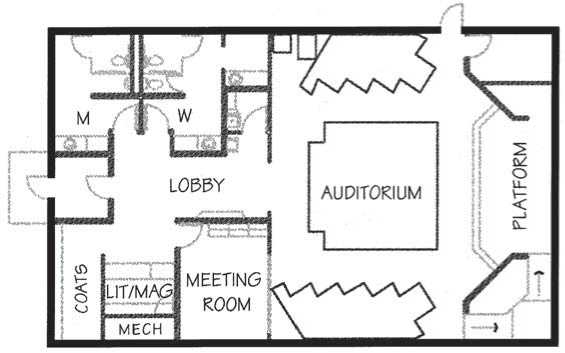

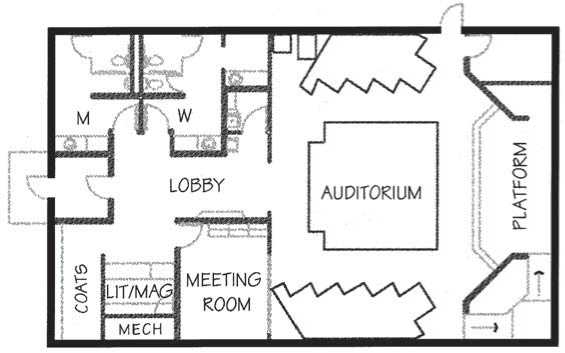

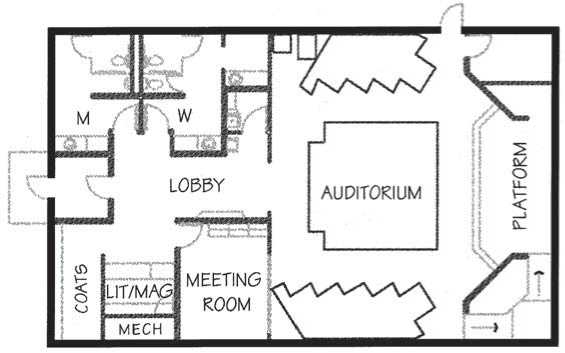

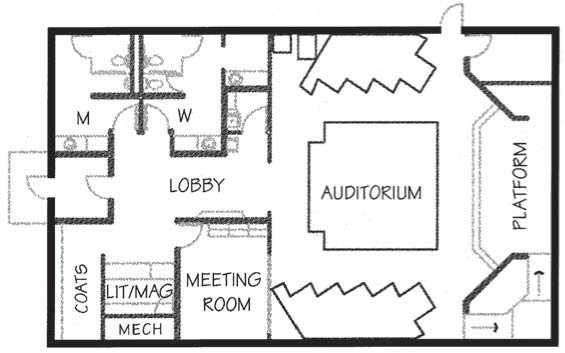

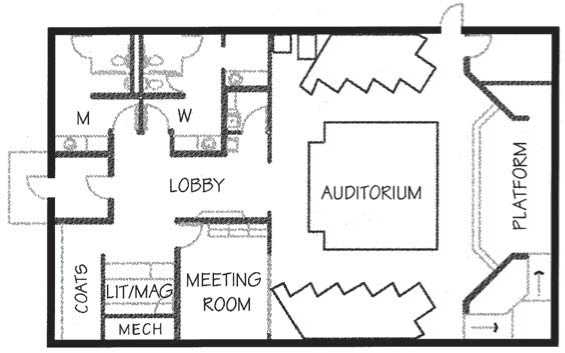

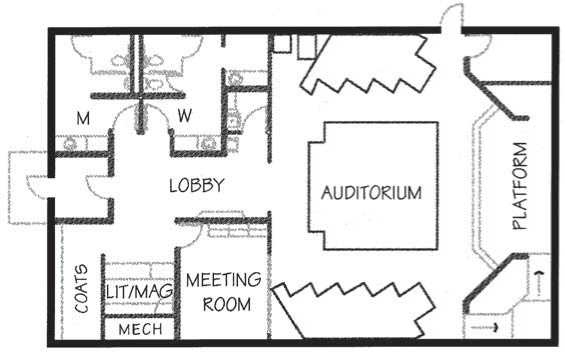

DESIGN 05 L-shaped floor plan.

Auditorium seating for 225.

T

—

DESIGN 06

Square-shaped floor plan.

Auditorium seating for 205.

B.

DESIGN 07 Rectangular floor plan with short end wall entry.

Auditorium seating for 96.

DESIGN 08 Rectangular floor plan with long side wall entry.

Auditorium seating for 96.

DOUBLE KINGDOM HALLS

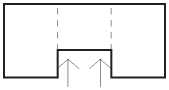

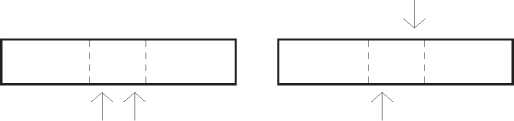

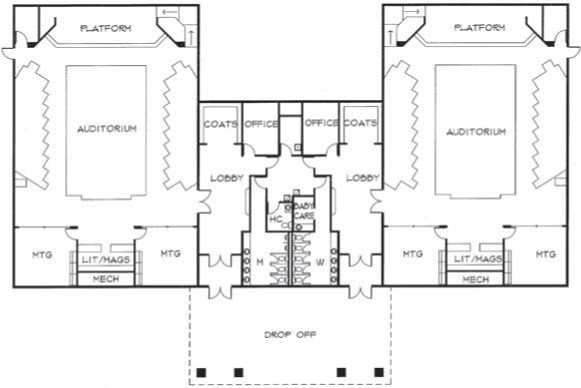

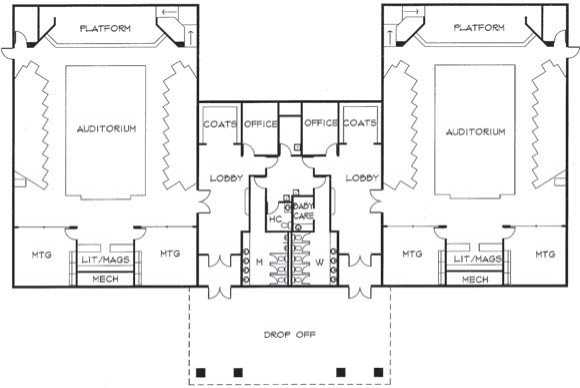

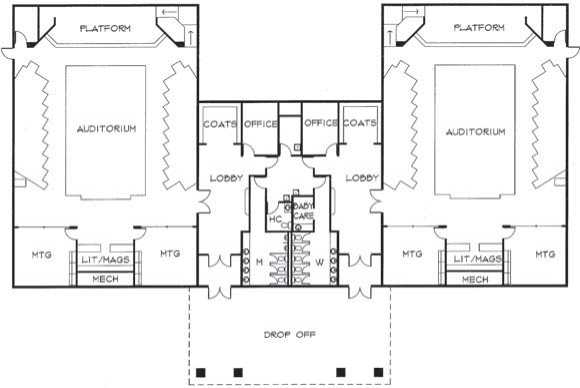

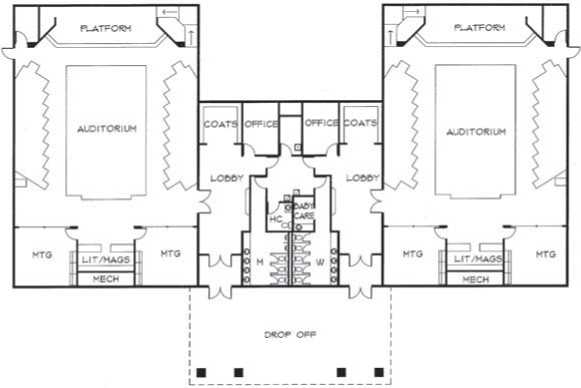

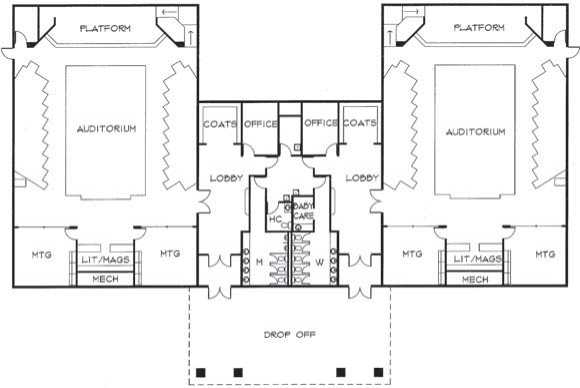

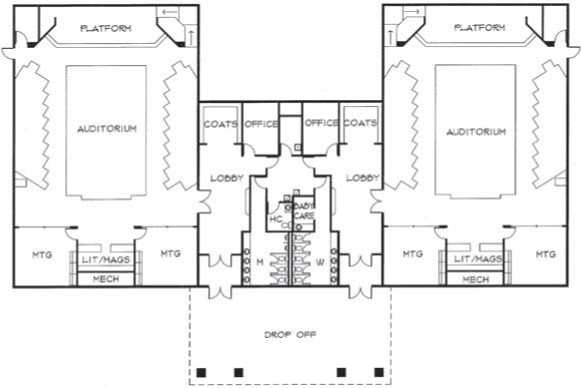

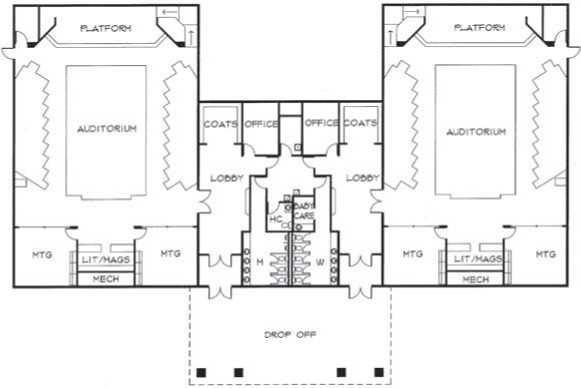

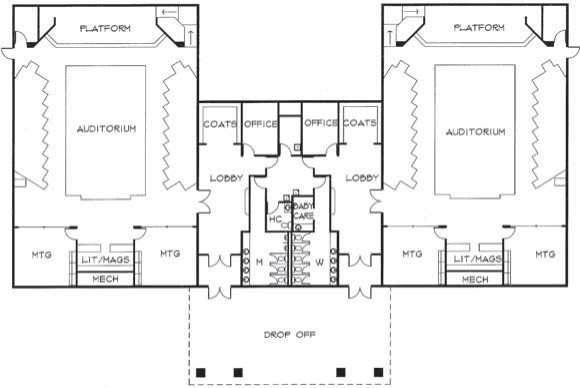

DESIGN NO. DESCRIPTION/COMMENTSDESIGN 10 U-shaped floor plan.

Each auditorium has seating for 225.

The core area or auditorium module can easily be mirrored to provide the following entry options:

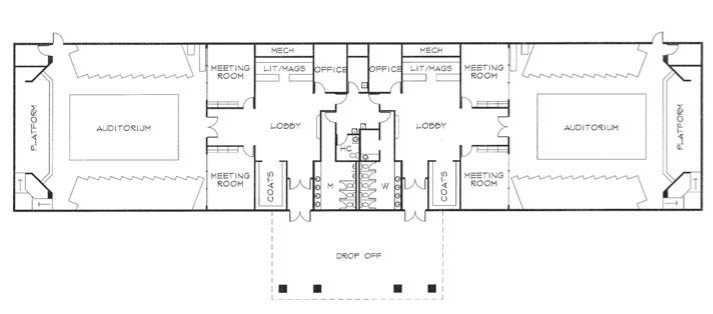

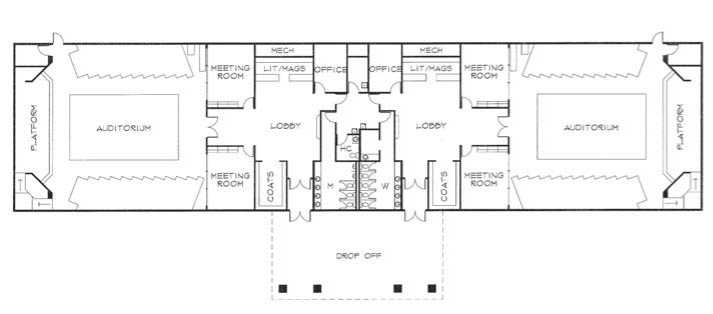

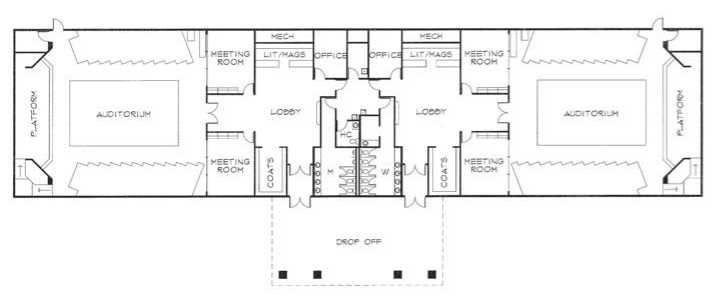

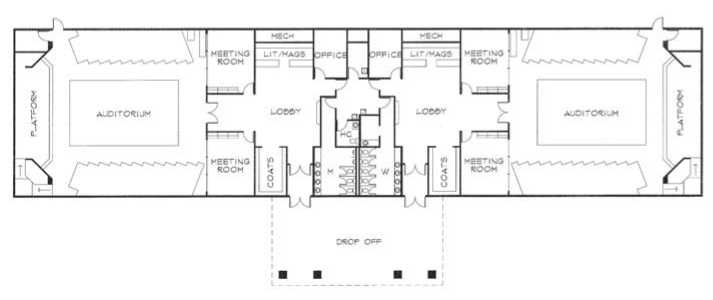

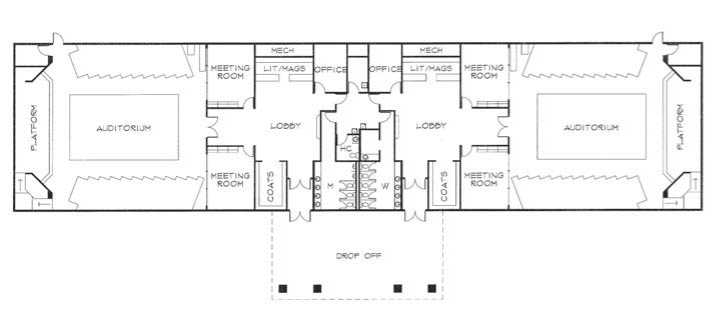

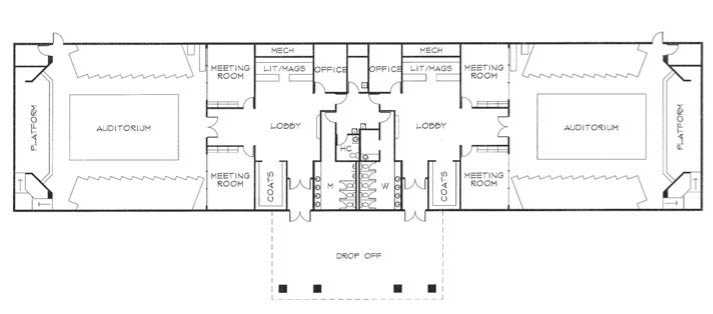

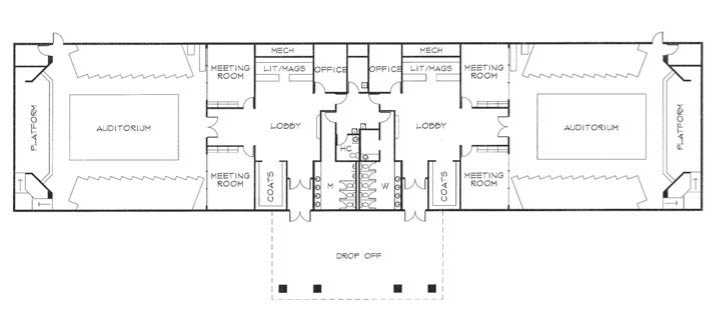

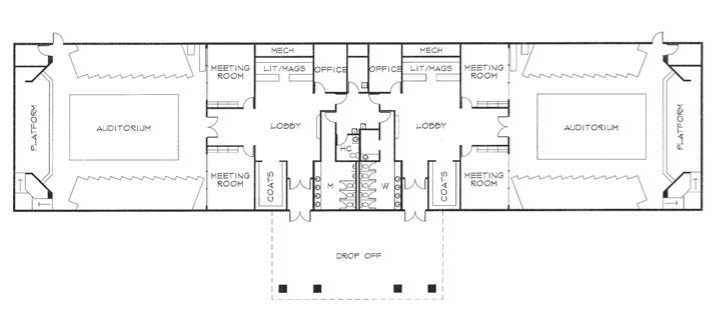

DESIGN 20 Long rectangular floor plan.

Each auditorium has seating for 225.

The core area can easily be mirrored to provide the following entry options:

C.

APARTMENT

-

1. A standard apartment design has been included. It is designed to share a common wall with the Kingdom Hall. The location of the apartment must be determined locally based on the specific site conditions.

-

III. ARCHITECTURAL CONSIDERATIONS

-

1. Auditorium: A 50-foot wide span allows the distance between the speaker on the platform and the last row of seating to be a maximum of 50 feet. This achieves optimum visual communication between the speaker and the last row of seating while maintaining an angle of encounter between the speaker and the first row of seating less than 130 degrees. The result is that the seating area is within the speaker’s peripheral spread of vision allowing for eye contact with the entire audience. Another design consideration specific to Kingdom Halls is to provide sufficient association space in the auditorium itself. This space makes it easier for the congregation to fellowship and circulate before and after the meetings. Aisle widths are 4 foot 6 inches to 5 feet that exceed minimum code requirements.

-

2. Platform: The platform area has been standardized in all designs. A ramp for wheelchair access along with storage areas for platform accessories is included. A continuous step along the front of the platform allows easy access for all meeting participants and those responsible for sound and platform adjustments during the meetings. The platform is 10 feet deep and 21 feet wide in small halls and 27 feet wide in large halls. This allows ample room for demonstrations and table discussions typically used for meeting parts. The storage room can be used for site maintenance and provided with an exterior door if so desired.

-

3. Meeting Rooms/Library: These rooms have been designed and located to serve multiple functions: overflow seating when required (e.g., Memorial, special talks, large congregations); second school and third school where required; book study location; meeting for field service location; congregation library. The entry to at least one of these rooms is located either in or near the lobby to provide access to the room with minimal disturbance to the main auditorium.

-

4. Office: A separate office is shown on all plans except for designs specifically for small congregations. It is typically used for congregation files, elders’ meetings, and shepherding. It is of increased value when more than one congregation uses the hall.

-

5. Literature and Magazine Counter: Each design includes a 12 foot counter with cabinets and 15 feet or 16 feet of storage cabinets. This provides enough storage space for use by multiple congregations. This function works well located in either the auditorium or lobby. Local authorities may dictate its location.

-

6. Lobby: The lobby area provides association space, circulation and access to the building’s facilities. Emphasis has been placed on the function of this space. The doors between the lobby and auditorium reduce noise and visual distraction.

-

7. Toilet Room Areas: The toilet rooms have been standardized in the single hall designs and double hall designs. A baby care/nursing area is provided in the women’s room and a baby change counter in the men’s room. A separate wheelchair accessible toilet room provides a practical area for use by a person confined to a wheelchair that is assisted by someone of the opposite sex, e.g., husband and wife, parent and child.

-

8. Coat Room: The coat room area is sized according to the AIA standard of allowing 1-1/2 inches of rack space per occupant. Openings into the coatroom are 5 feet minimum to help reduce congestion.

-

9. Vestibule: A vestibule has been incorporated in all designs. This provides an airlock in severe climates and a noise barrier from the exterior. If a vestibule is not considered advantageous in a specific application, it can be eliminated from the design.

-

10. Drop-Off/Drive-Through: A drive-through is recommended but optional on all designs. Along with providing protection from inclement weather, a drive-through has a major impact on the aesthetics of the building and should therefore be treated accordingly. Local codes may dictate specific requirements.

-

11. Heating/Cooling and Moisture Control: It is recommended that the exterior design reflect consideration of the local environment, site orientation, and climactic conditions. In most climates, and especially in warm, humid areas, special attention must be given to the design of the building envelope and the heating, ventilation, and air-conditioning (HVAC) system so as to reduce the potential for mold growth and associated indoor air quality problems. The local registered design professional should be consulted in determining the appropriate design.

-

1. Warm Climates: In many parts of the country, a large coatroom and vestibule is not required. The space allocated for these can easily be redistributed to the lobby, office or meeting room along with providing a small coat hanging area.

-

2. Ceiling: The finished ceilings for all designs are suspended acoustic lay-in tiles 2 by 2 feet. Drywall ceilings are optional.

-

3. Cabinets: Detail drawings for report counters, literature counters, information boards and similar cabinetwork have been included in the drawing package. These are suggestions that could be adapted to suit local needs.

-

1. Concept: The design concept for the exterior treatment is based on keeping the bulk of

the building simple while focusing interest on the entry area. This results in keeping construction time and costs down while at the same time providing aesthetically pleasing enhancements located where they will be most appreciated. Attention should be given to the entry doors, and their immediate surroundings including decorative lighting and column covers.

-

2. Roof: Each design is available with either a hipped or gable roof.

-

3. Exterior Wall Finish options include:

-

a. Brick veneer.

-

b. Siding (wood, vinyl or aluminum).

-

c. Stucco.

-

d. Brick wainscot with siding (wood, vinyl or aluminum) above.

-

4. Windows: Windows are optional for all designs. If used, they must be designed and located locally.

-

5. Exterior Doors: For security reasons, the only exterior doors indicated on the drawings

are those required for egress. Additional doors from other spaces, such as office, meeting room or storage spaces, are optional.

-

IV. CIVIL CONSIDERATIONS

-

1. For practical purposes civil drawings are not included in the standard design package. However, standard details have been included for reference.

-

2. The following list of items may be considered in the preparation of civil drawings: a. Vicinity Map b. Property Size

-

c. Legal Setback Lines

-

d. Easements

-

e. Survey

-

f. Description of Soil Type and Bearing

-

g. Percolation Test Plan

-

h. Soil Borings and Testing Schedule and Profile

-

i. Test Boring Locations

-

j. Excavation

-

k. Demolition and Repair

-

l. Grading

-

m. Soil Compaction

n. Site Drainage o. Erosion Control p. Retaining Walls q. Fences and Gates r. Signs

-

s. Utilities (e.g., storm, sewer, and water)

-

t. Septic System (if required)

-

u. Paving, Walkways, and Parking

-

v. Parking for Handicapped

-

w. Pavement Marking

-

x. Protective Vehicular Curbs, Bumpers, and Guard Railings

y. Landscaping

z. Landscape Maintenance Storage Shelter

-

V. STRUCTURAL CONSIDERATIONS

-

1. A slab on grade is shown as typical.

-

2. The standard design is load bearing exterior walls of 2-by-6-inch wood studs at 16 inches on center. Light gage steel studs or masonry units may also be used if economical and compatible with the abilities of the Regional Building Committee involved or if required by local building codes.

-

3. The standard roof design is wood trusses at 24 inches on center with a roof pitch of 5 to 12. The roof pitch may be adjusted to suit local needs. The trusses span a distance of 50 feet for the larger single halls and double halls and 44 feet for smaller halls.

-

B. DESIGN INFORMATION

-

a. Design criteria required by the local building department should be provided on the drawings.

-

b. The registered design professional is responsible and liable for the structural design and integrity of the building. It is recommended that the regional committee coordinate with the registered design professional to determine appropriate structural requirements to be followed. The following information is being provided as an aid to the registered design professional regarding areas needing attention. This is in no way intended to be comprehensive or complete.

-

a. Designing footings for a soil bearing strength of 1,000 psf usually makes it unnecessary to engage a soils engineer. However, local building officials may require the use of a soils engineer, especially if the site is sloped, includes filled ground, contaminated soil, expansive soils, ground water or drainage problems.

-

a. Roof trusses are generally purchased from a manufacturer. Provide design requirements for their use in preparing the design of the trusses.

-

b. The roof-framing plan must show the bracing system for diaphragm action to resist lateral loads.

-

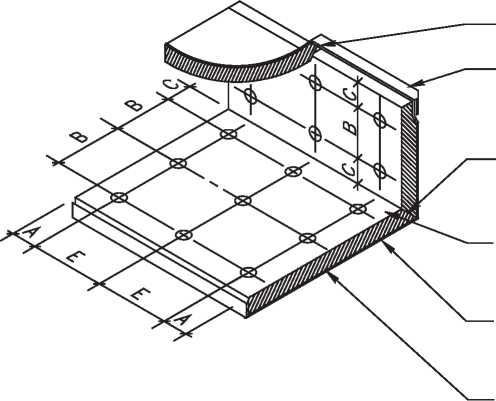

a. Design plywood horizontal and vertical diaphragms for lateral wind and seismic loads. Show nailing patterns on the roof drawings for plywood edges, diaphragm boundary and intermediate framing members.

-

b. Shear nailing must provide a continuous load path from the roof boundary, through the blocking to the walls. Metal clips are generally required to transmit the shear from the blocking to the top plate where the wall sheathing is attached for shear transfer to the foundation. Building codes usually specify nail type, size, and spacing. Field inspection may be required.

-

c. Minimum size and spacing of anchor bolts for connecting the bottom plate of the walls to the foundation should be specified.

-

d. The drawings must show top plate splice details when used as a diaphragm chord.

-

e. Special attention should be given to the lateral stability of drive-throughs and their

foundations. These may require larger seismic load factors than that utilized for the building, and are also subject to wind uplift loads.

-

f. Shear walls must be designed and detailed (including anchorage) for overturning stability.

-

g. When a gypsum board ceiling is used, the ceiling diaphragm may provide adequate bracing for the gable end walls. However, when a suspended acoustical ceiling is used and there are no interior partitions to adequately support the wall, bracing may be required for lateral loads.

-

VI. MECHANICAL SYSTEMS CONSIDERATIONS

-

1. The plumbing areas have been centralized in all designs including the utilization of a back-to-back plumbing chase. This will result in time and cost savings.

-

2. Floor outlet toilets have been specified due to their low initial cost, low water consumption, and minimal maintenance.

-

3. There are no fixtures located on the exterior walls in order to reduce potential freezing problems in cold climates.

-

4. The water heater is located in the utility room for close proximity to fixtures using hot water. The relief valve from the water heater may discharge directly into the service sink.

-

5. The water meter, if required, should be located in the utility room. In a non-freeze climate, it may be installed outside.

-

6. Gas piping and gas meter installation shall conform to local codes, as well as requirements of the local fuel distributor. Ideally, the gas meter should be located near the HVAC units.

-

1. The standard heating and cooling system consists of unitary packaged units mounted on the ground with a gas heating furnace section and electric cooling compressors. Where natural gas service is not available, a liquid petroleum gas (LPG) tank may be substituted. Contact the local fuel distributor for quantity, size, and location of tanks. In warmer climates, packaged electric or heat pump units may be utilized.

-

2. The advantages of a unitary system are as follows:

-

a. Relatively low initial cost.

-

b. Minimal annual maintenance required.

-

c. Reasonably simple installation.

-

d. No refrigeration piping work required.

-

e. No mechanical equipment room is required inside the building.

-

f. Relatively quiet operation.

-

3. Three five-ton units are specified for the larger halls. Two five-ton units are specified for the smaller halls. Where three-phase electrical service is readily available, one ten-ton unit may be substituted for two five-ton units. An in-duct smoke detector may be required for a ten-ton unit.

-

4. The HVAC units are located on concrete pads outside the building. An enclosure for security may be provided. If the site dictates or snowfall is excessive, the units may be elevated or installed on the roof. If a roof installation is used, adjustments to the roof trusses and roof finishes should be considered.

-

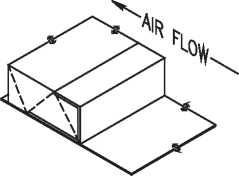

5. The distribution system for both heating and cooling is via ductwork located in the attic space.

-

6. Air is exhausted from the bathroom areas and the utility room to the exterior. The exhaust outlet must be located away from the property line and any other openings into the building, in accordance with local codes.

-

7. In order to provide proper ventilation and fresh air, the HVAC system, including bathroom exhaust, is designed to run continuously during occupied periods. Occupied periods may be set by means of a seven-day programmable thermostat. It is recommended that the thermostat(s) be made inaccessible, to prevent tampering with the program. A remote sensor with the capability to temporarily override the program is located conveniently within the conditioned space.

-

8. Where practical, the HVAC system for the lobby and meeting rooms area is separate from that of the auditorium. Thus, in the event of a small meeting, such as a book study, the entire building need not be air-conditioned.

-

9. There are many variables to consider in selecting an appropriate mechanical system, e.g., utilities available, type of fuel, local cost of utilities. The Regional Building Committee may need to make adjustments to the design to accommodate local needs.

-

1. Prepare an operation and maintenance manual with the following information:

-

a. Description of function, normal operating characteristics and limitations, performance curves, engineering data and tests, and complete nomenclature and commercial numbers of replacement parts.

-

b. Manufacturer’s printed operating procedures.

-

c. Maintenance procedures for routine preventative maintenance and troubleshooting.

-

d. Servicing instructions and lubrication charts and schedules.

-

VII. ELECTRICAL CONSIDERATIONS

-

1. The auditorium is designed to provide an initial footcandle level of 50. The auxiliary areas are designed to provide at least an initial footcandle level of 35. The emergency lighting system is designed to provide a footcandle level of two. These lighting levels are based on finished surfaces with average reflectance. If dark colors are used, additional lighting may be required to attain these levels.

-

2. The designs include a security system that can be utilized if necessary.

-

3. The designs include a fire alarm system that can be utilized if required or desired.

-

4. The speaker layout is based on a 90-degree dispersion pattern for a 4-inch speaker. Uniform sound coverage in the auditorium is of utmost importance. For a design ceiling height of 9 feet 6 inches, the ceiling mounted speakers are placed in a square pattern at 8 feet on center with minimum overlap to eliminate dead spots.

-

5. See Specification A for sound system specifications.

-

1. Use copper wire only, aluminum wire is not recommended.

-

2. Use #12 TW or THW solid conductor wire 20-A circuits.

-

3. Pull colored wire for items such as switch legs (the more colors used, the easier the identification).

-

4. Use stranded conductors, THW or THHN for #10 awg wire size and above (service entrance conductors may also be THW or SE cable).

-

5. Use electrical metallic tubing (EMT) conduit with setscrew type fittings for use as the ground conductor. Home runs are 3/4-inch minimum.

-

6. Use rigid (steel or PVC) conduit at service entrance. If service is underground, install conduit for that portion that is under paving or concrete.

-

7. Use duplex outlets (20 A, 2 pole, 3 wire) with screw-type wire terminals, self-grounding and standard grade.

-

8. Use switches with a 20-A rating for auditorium lights. Use 15-A switches elsewhere, all standard grade.

-

9. The authority having jurisdiction may allow:

-

a. Items such as non-metallic sheathed cable, rigid non-metallic conduit, and flexible metal conduit.

-

b. Outlet circuits to be tied-in to nearest lighting circuit. If this is considered, remember that heavy loads may be plugged into them (e.g., carpet cleaning equipment).

-

10. The authority having jurisdiction may require:

-

a. EMT to have compression fittings.

-

b. Lighting and general receptacle circuits to be on 15-A circuit breakers with #12 wire.

-

c. Underground conduits to be of a certain material.

-

d. Telephone cables to be in conduit.

-

e. Public address cables to be in conduit. If so, route in separate conduits from alternating current (ac) wiring and keep microphone cables separate from speaker cables.

-

f. Smoke detectors.

-

g. Exit light letters to be 8-inches high in places of assembly.

-

1. Determine clearly what the authority having jurisdiction will or will not accept in the specification of materials and installation procedures. This should be done well in advance of construction.

-

2. Well in advance of construction, check with the power company supplying electricity as to:

-

a. Meter base requirements (for various ampacities), voltages and phases available (e.g., 120/240 V, 1 Phase; 120/208 V, 3 Phase).

-

b. Whether overhead or underground services are available or required (some areas require a more expensive underground service).

-

c. Kind and size of conduit service entrance system to be used.

-

d. Meter wiring and color-coding.

-

e. A kilowatt-hour cost savings for separate metering of air conditioning circuits. If advantageous, install the extra meter and panel required.

-

f. Whether a temporary power service will be required. Some power companies will not supply power to the final building service entrance panel until the building is completely built and inspected. If allowed, construct a short wall at the final service entrance panel, install the electrical panel and service, get this inspected, and have the power turned on before the start of the construction.

-

3. Where conduit is to be installed underground or in a concrete slab to serve wall outlets, or a public address (P.A.) system, use rigid conduit all the way back to the panel location.

-

4. Route wiring for outlets in conduit separate from lighting.

-

5. Clearly identify all circuits on panel directory, making as-built notations on a good copy of the electrical drawings. If possible, and as time permits, label destinations with their circuit numbers.

-

1. Mount a temporary sign over any uncovered, energized panel or piece of equipment clearly stating in large letters, “CAUTION! ENERGIZED PANEL.”

-

2. As new circuits are energized for testing, make sure all personnel involved are notified. Check for possible wiring mistakes that could energize other wires. It is suggested that only one or two persons be authorized to energize circuits.

-

3. Since the lighting/power panel will most likely be energized during construction, it is suggested that metal fish tapes be used with caution. Where possible, push tapes away from panel instead of into panel.

-

VIII. APPENDICES

-

A. APPENDIX A—CAD DRAWING FILE CONSIDERATIONS

-

a. All drawings use an 11-by-17-inch format.

-

b. The Standard Kingdom Hall Designs have been provided in CAD format for your convenience. The files are provided in both AutoCAD Release 14 and 2000 drawing formats.

-

c. The drawings have been updated to use the standard RomanS font that comes with AutoCAD.

-

d. Copy the files from the CD-ROM over to your local hard drive. Maintaining the CAD files in the same relative directory locations will enable AutoCAD to locate the required external reference files (xrefs) correctly If you are not familiar with the use of xrefs, it is recommended that you read the AutoCAD manual under xref. The Standard Kingdom Hall Designs CAD files utilize xrefs for basesheets and clips. The following section describes the use of basesheets and clips.

-

a. The basesheet concept makes use of the external reference feature of AutoCAD. Since the base architectural information is used by each of the disciplines, such as mechanical and electrical, this information is shared, rather than redrawn. The base architectural information is placed in the ..\BASEdirectory. From the ..\BASEdirectory, each discipline inserts the architectural base information as an xref. This concept assists coordination between disciplines.

-

b. When a change to the architectural floor plan is made, then the basesheet xref must be updated.

-

c. Each discipline that uses the basesheet will automatically be updated.

-

d. Clips are xrefs used much like basesheets However, they only show a portion of the architectural plan.

-

e. Whenever an architectural change is made, it is best to update the xrefs in the drawing as well.

-

a. WBLOCK (the entire floor plan out to the ..\BASEdirectory to update the basesheet. The name of the block can be found in the lower left corner of the drawing. The insertion point of the basesheet is 0,0. Refer to the AutoCAD manual if you require information about using the WBLOCK command.

-

b. If your drawing was used to generate clips, there will be clip borders drawn on layer 1-CLIP. You may update clips by WBLOCKing all of the information contained within the clip. The clip name will be displayed in the lower right hand corner of the clip border and its insertion point will be represented by a circle on the 1-CLIP layer, within the clip border. The clip should also be WBLOCKed to the ..\BASEdirectory. Thereafter, open the clip drawing and trim the entities which extend outside of the clip border.

-

a. Organized use of layers makes it easy to manage the information in the drawings. Appendix B provides a reference of the layers used for the creation of these drawings. Conversion to any other system, such as the AIA CAD Layer Guidelines, is optional.

-

a. Two separate color assignment tables, called NO SCREEN and BASESHEET, have been provided. The NO SCREEN table screens colors 55, 113, 135, and 250-254. BASESHEET additionally screens colors 7 and 8 which is suitable for plotting drawings that have included the architectural plans in them as xrefs. The actual file extension for the color assignment table varies depending on the version of AutoCAD. For R2000 it is CTB, and for R14 and older versions it is provided as a PCP.

-

1. Color Assignments: Colors are a visual aid, often used to identify layers. Additionally, each color has a plotted line weight (as assigned in the CTB file). The colors are arranged so that brighter colors, which stand out on the display screen, will depict thicker lines. Darker colors, which fade into the display screen, will represent thinner lines. Actual color, as indicated by the column labeled COLOR NUMBER may vary from system to system depending on the hardware factors such as the monitor or video card. These colors are best viewed with a black background in AutoCAD.

2.

Common Layer Assignments

COLOR GROUP

COLOR NUMBER

PLOTTED LINE WIDTH

DISPLAY COLOR

Red

244

.08 mm .0031 in

Burgundy

1

.15 mm .0059 in

Red

221

.35 mm .0138 in

Pale Magenta

6

.50 mm .0197 in

Magenta

Blue

185

.05 mm .0019 in

Purple

140

.15 mm .0059 in

Dark Cyan

150

.15 mm .0059 in

Medium Blue

165

.25 mm .0098 in

Blue Gray

171

.35 mm .0138 in

Light Purple

4

.70 mm .0276 in

Cyan

5

.70 mm .0276 in

Dark Blue

205

2.00 mm .0787 in

Dark Purple

Gray

8

.15 mm .0059 in

Dark Gray

254

.35 mm .0138 in

Light Gray

7

.50 mm .0197 in

White

Yellow

41

.15 mm .0059 in

Wheat

30

.15 mm .0059 in

Orange

2

.35 mm .0138 in

Yellow

53

.70 mm .0276 in

Mustard

21

1.00 mm .0394 in

Clay

Green

85

.12 mm .0047 in

Dark Olive

101

.15 mm .0059 in

Pale Green

84

.35 mm .0138 in

Dark Green

3

.50 mm .0197 in

Green

113

.25 mm .0098 in

Light Green

55

.30 mm .0118 in

Olive

135

.40 mm .0157 in

Teal

Gray

8

.35 mm .0138 in

Dark Gray

7

.50 mm .0197 in

White

255

.35 mm .0138 in

Very Light Grey

253

.35 mm .0138 in

Light Grey

251

.35 mm .0138 in

Dark Grey

252

.50 mm .0197 in

Medium Grey

LAYER #

COLORS

INFORMATION TYPE

0

7

Layer 0 is an AutoCAD standard.

Most blocks are drawn on layer 0.

Layer 0 should never be frozen or turned off.

Defpoints

7

AutoCAD standard layer for dimension points.

Items placed on defpoints will never plot.

95

1

Detail format border.

96

1, 2

Designer’s notes (normally “frozen”- ref. only)

99

1, 6, 53, 221

Normal format borders

Basesheet Color Assignment Table

|

Color # |

Basesheet | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

1 |

7 |

.15 |

.15 |

.15 |

|

2 |

7 |

.35 |

.20 |

.15 |

|

3 |

7 |

.50 |

.30 |

.15 |

|

4 |

7 |

.70 |

.40 |

.15 |

|

5 |

7 |

.70 |

.40 |

.15 |

|

6 |

7 |

.50 |

.30 |

.15 |

|

7 |

252 |

.50 |

.30 |

.20 |

|

8 |

252 |

.25 |

.20 |

.20 |

|

9 |

7 |

.70 |

.40 |

.15 |

|

10 |

7 |

.15 |

.15 |

.15 |

|

11 |

7 |

.35 |

.20 |

.15 |

|

12 |

7 |

.15 |

.15 |

.15 |

|

13 |

7 |

.35 |

.20 |

.15 |

|

14 |

7 |

.35 |

.20 |

.15 |

|

15 |

252 |

.25 |

.20 |

.20 |

|

16 |

16 |

.35 |

.20 |

.15 |

|

17 |

17 |

.35 |

.20 |

.15 |

|

18 |

18 |

.35 |

.20 |

.15 |

|

19 |

19 |

.35 |

.20 |

.15 |

|

20 |

23 |

.25 |

.25 |

.20 |

|

21 |

71 |

1.0 .50 .15 | ||

|

22 |

23 |

.50 |

.35 |

.20 |

|

23 |

23 |

.70 |

.40 |

.20 |

|

24 |

23 |

.35 |

.25 |

.20 |

|

25 |

25 |

.35 |

.25 |

.20 |

|

26 |

26 |

.35 |

.25 |

.20 |

|

27 |

27 |

.35 |

.25 |

.20 |

|

28 |

28 |

.35 |

.25 |

.20 |

|

29 |

29 |

.35 |

.25 |

.20 |

|

30 |

7 |

.15 |

.15 |

.15 |

|

31 |

30 |

.35 |

.25 |

.15 |

|

32 |

30 |

.50 |

.35 |

.15 |

|

33 |

30 |

.70 |

.40 |

.15 |

|

34 |

30 |

.20 |

.20 |

.15 |

|

35 |

35 |

.35 |

.20 |

.15 |

|

36 |

36 |

.35 |

.20 |

.15 |

|

37 |

37 |

.35 |

.20 |

.15 |

|

38 |

38 |

.35 |

.20 |

.15 |

|

39 |

39 |

.35 |

.20 |

.15 |

|

40 |

40 |

.25 |

.25 |

.20 |

|

41 | ||||

|

42 |

40 |

.50 |

.35 |

.20 |

|

43 |

40 |

.70 |

.40 |

.20 |

|

44 |

40 |

.35 |

.25 |

.20 |

|

45 |

45 |

.35 |

.25 |

.20 |

|

46 |

46 |

.35 |

.25 |

.20 |

|

47 |

47 |

.35 |

.25 |

.20 |

|

48 |

48 |

.35 |

.25 |

.20 |

|

49 |

49 |

.35 |

.25 |

.20 |

|

50 |

2 |

.25 |

.25 |

.20 |

|

51 |

2 |

.35 |

.25 |

.20 |

|

52 |

2 |

.50 |

.35 |

.20 |

|

53 |

■SK3 |

.40 |

.15 | |

|

54 |

2 |

.70 |

.40 |

.20 |

|

55 |

251 |

.30 |

.20 |

.20 |

|

56 |

56 |

.35 |

.25 |

.20 |

|

57 |

57 |

.35 |

.25 |

.20 |

|

58 |

58 |

.35 |

.25 |

.20 |

|

59 |

59 |

.35 |

.25 |

.20 |

|

60 |

60 |

.25 |

.25 |

.20 |

|

61 |

60 |

.35 |

.25 |

.20 |

|

62 |

60 |

.50 |

.35 |

.20 |

|

63 |

60 |

.70 |

.40 |

.20 |

|

64 |

64 |

.35 |

.25 |

.20 |

|

Color # |

Basesheet | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

65 |

65 |

.35 |

.25 |

.20 |

|

66 |

66 |

.35 |

.25 |

.20 |

|

67 |

67 |

.35 |

.25 |

.20 |

|

68 |

68 |

.35 |

.25 |

.20 |

|

69 |

69 |

.35 |

.25 |

.20 |

|

70 |

71 |

.25 |

.25 |

.20 |

|

71 |

71 |

.35 |

.25 |

.20 |

|

72 |

71 |

.50 |

.35 |

.20 |

|

73 |

71 |

.70 |

.40 |

.20 |

|

74 |

74 |

.35 |

.25 |

.20 |

|

75 |

75 |

.35 |

.25 |

.20 |

|

76 |

76 |

.35 |

.25 |

.20 |

|

77 |

77 |

.35 |

.25 |

.20 |

|

78 |

78 |

.35 |

.25 |

.20 |

|

79 |

79 |

.35 |

.25 |

.20 |

|

80 |

80 |

.20 |

.20 |

.15 |

|

81 |

80 |

.35 |

.25 |

.15 |

|

82 |

80 |

.50 |

.35 |

.15 |

|

83 |

80 |

.70 |

.40 |

.15 |

|

84 |

7 |

.35 |

.20 | |

|

85 |

7 |

.12 .12 .12 | ||

|

86 |

86 |

.35 |

.20 |

.15 |

|

87 |

87 |

.35 |

.20 |

.15 |

|

88 |

88 |

.35 |

.20 |

.15 |

|

89 |

89 |

.35 |

.20 |

.15 |

|

90 |

3 |

.20 |

.20 |

.15 |

|

91 |

3 |

.35 |

.25 |

.15 |

|

92 |

3 |

.50 |

.35 |

.15 |

|

93 |

3 |

.70 |

.40 |

.15 |

|

94 |

94 |

.35 |

.20 |

.15 |

|

95 |

95 |

.35 |

.20 |

.15 |

|

96 |

96 |

.35 |

.20 |

.15 |

|

97 |

97 |

.35 |

.20 |

.15 |

|

98 |

98 |

.35 |

.20 |

.15 |

|

99 |

99 |

.35 |

.20 |

.15 |

|

100 |

93 |

.25 |

.25 |

.20 |

|

101 |

71 |

.15 |

.15 |

.15 |

|

102 |

93 |

.50 |

.35 |

.20 |

|

103 |

93 |

.70 |

.40 |

.20 |

|

104 |

93 |

.35 |

.25 |

.20 |

|

105 |

105 |

.35 |

.25 |

.20 |

|

106 |

106 |

.35 |

.25 |

.20 |

|

107 |

107 |

.35 |

.25 |

.20 |

|

108 |

108 |

.35 |

.25 |

.20 |

|

109 |

109 |

.35 |

.25 |

.20 |

|

110 |

110 |

.20 |

.20 |

.15 |

|

111 |

110 |

.35 |

.25 |

.15 |

|

112 |

110 |

.50 |

.35 |

.15 |

|

113 |

252 |

.25 |

.20 |

.20 |

|

114 |

110 |

.70 |

.40 |

.15 |

|

115 |

115 |

.35 |

.20 |

.15 |

|

116 |

116 |

.35 |

.20 |

.15 |

|

117 |

117 |

.35 |

.20 |

.15 |

|

118 |

118 |

.35 |

.20 |

.15 |

|

119 |

119 |

.35 |

.20 |

.15 |

|

120 |

120 |

.20 |

.20 |

.15 |

|

121 |

120 |

.35 |

.25 |

.15 |

|

122 |

120 |

.50 |

.35 |

.15 |

|

123 |

120 |

.70 |

.40 |

.15 |

|

124 |

124 |

.35 |

.20 |

.15 |

|

125 |

125 |

.35 |

.20 |

.15 |

|

126 |

126 |

.35 |

.20 |

.15 |

|

127 |

127 |

.35 |

.20 |

.15 |

|

128 |

128 |

.35 |

.20 |

.15 |

|

Color # |

Basesheet | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

129 |

129 |

.35 |

.20 |

.15 |

|

130 |

4 |

.20 |

.20 |

.15 |

|

131 |

4 |

.35 |

.25 |

.15 |

|

132 |

4 |

.50 |

.35 |

.15 |

|

133 |

4 |

.70 |

.40 |

.15 |

|

134 |

134 |

.35 |

.20 |

.15 |

|

135 |

252 |

.40 |

.25 |

.20 |

|

136 |

136 |

.35 |

.20 |

.15 |

|

137 |

137 |

.35 |

.20 |

.15 |

|

138 |

138 |

.35 |

.20 |

.15 |

|

139 |

139 |

.35 |

.20 |

.15 |

|

140 |

71 |

.15 |

.15 |

.15 |

|

141 |

140 |

.35 |

.25 |

.15 |

|

142 |

140 |

.50 |

.35 |

.15 |

|

143 |

140 |

.70 |

.40 |

.15 |

|

144 |

144 |

.35 |

.20 |

.15 |

|

145 |

140 |

.20 |

.20 |

.15 |

|

146 |

146 |

.35 |

.20 |

.15 |

|

147 |

147 |

.35 |

.20 |

.15 |

|

148 |

148 |

.35 |

.20 |

.15 |

|

149 |

149 |

.35 |

.20 |

.15 |

|

150 |

71 |

.15 |

.15 |

.15 |

|

151 |

150 |

.35 |

.25 |

.15 |

|

152 |

150 |

.50 |

.35 |

.15 |

|

153 |

150 |

.70 |

.40 |

.15 |

|

154 |

150 |

.20 |

.20 |

.15 |

|

155 |

155 |

.35 |

.20 |

.15 |

|

156 |

156 |

.35 |

.20 |

.15 |

|

157 |

157 |

.35 |

.20 |

.15 |

|

158 |

158 |

.35 |

.20 |

.15 |

|

159 |

159 |

.35 |

.20 |

.15 |

|

160 |

160 |

.20 |

.20 |

.15 |

|

161 |

160 |

.35 |

.25 |

.15 |

|

162 |

160 |

.50 |

.35 |

.15 |

|

163 |

160 |

.70 |

.40 |

.15 |

|

164 |

164 |

.35 |

.20 |

.15 |

|

165 |

.15 |

.15 | ||

|

166 |

166 |

.35 |

.20 |

.15 |

|

167 |

167 |

.35 |

.20 |

.15 |

|

168 |

168 |

.35 |

.20 |

.15 |

|

169 |

169 |

.35 |

.20 |

.15 |

|

170 |

5 |

.20 |

.20 |

.15 |

|

171 |

71 |

.35 .20 .15 | ||

|

172 |

5 |

.50 |

.35 |

.15 |

|

173 |

5 |

.70 |

.40 |

.15 |

|

174 |

174 |

.35 |

.20 |

.15 |

|

175 |

5 |

.35 |

.25 |

.15 |

|

176 |

176 |

.35 |

.20 |

.15 |

|

177 |

177 |

.35 |

.20 |

.15 |

|

178 |

178 |

.35 |

.20 |

.15 |

|

179 |

179 |

.35 |

.20 |

.15 |

|

180 |

182 |

.20 |

.20 |

.15 |

|

181 |

182 |

.35 |

.25 |

.15 |

|

182 |

182 |

.50 |

.35 |

.15 |

|

183 |

182 |

.70 |

.40 |

.15 |

|

184 |

184 |

.35 |

.20 |

.15 |

|

185 |

71 |

.05 .05 .05 | ||

|

186 |

186 |

.35 |

.20 |

.15 |

|

187 |

187 |

.35 |

.20 |

.15 |

|

188 |

188 |

.35 |

.20 |

.15 |

|

189 |

189 |

.35 |

.20 |

.15 |

|

190 |

190 |

.20 |

.20 |

.15 |

|

191 |

190 |

.35 |

.25 |

.15 |

|

192 |

190 |

.50 |

.35 |

.15 |

|

Color # |

Basesheet | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

193 |

190 |

.70 |

.40 |

.15 |

|

194 |

194 |

.35 |

.20 |

.15 |

|

195 |

195 |

.35 |

.20 |

.15 |

|

196 |

196 |

.35 |

.20 |

.15 |

|

197 |

197 |

.35 |

.20 |

.15 |

|

198 |

198 |

.35 |

.20 |

.15 |

|

199 |

199 |

.35 |

.20 |

.15 |

|

200 |

200 |

.20 |

.20 |

.15 |

|

201 |

200 |

.35 |

.25 |

.15 |

|

202 |

200 |

.50 |

.35 |

.15 |

|

203 |

200 |

.70 |

.40 |

.15 |

|

204 |

204 |

.35 |

.20 |

.15 |

|

205 |

■■EE |

1.0 |

.15 | |

|

206 |

206 |

.35 |

.20 |

.15 |

|

207 |

207 |

.35 |

.20 |

.15 |

|

208 |

208 |

.35 |

.20 |

.15 |

|

209 |

209 |

.35 |

.20 |

.15 |

|

210 |

6 |

.20 |

.20 |

.15 |

|

211 |

6 |

.35 |

.25 |

.15 |

|

212 |

6 |

.50 |

.35 |

.15 |

|

213 |

6 |

.70 |

.40 |

.15 |

|

214 |

214 |

.35 |

.20 |

.15 |

|

215 |

215 |

.35 |

.20 |

.15 |

|

216 |

216 |

.35 |

.20 |

.15 |

|

217 |

217 |

.35 |

.20 |

.15 |

|

218 |

218 |

.35 |

.20 |

.15 |

|

219 |

219 |

.35 |

.20 |

.15 |

|

220 |

220 |

.20 |

.20 |

.15 |

|

221 |

.35 |

.20 |

.15 | |

|

222 |

220 |

.50 |

.35 |

.15 |

|

223 |

220 |

.70 |

.40 |

.15 |

|

224 |

224 |

.35 |

.20 |

.15 |

|

225 |

220 |

.35 |

.25 |

.15 |

|

226 |

226 |

.35 |

.20 |

.15 |

|

227 |

227 |

.35 |

.20 |

.15 |

|

228 |

228 |

.35 |

.20 |

.15 |

|

229 |

229 |

.35 |

.20 |

.15 |

|

230 |

230 |

.20 |

.20 |

.15 |

|

231 |

230 |

.35 |

.25 |

.15 |

|

232 |

230 |

.50 |

.35 |

.15 |

|

233 |

230 |

.70 |

.40 |

.15 |

|

234 |

234 |

.35 |

.20 |

.15 |

|

235 |

235 |

.35 |

.20 |

.15 |

|

236 |

236 |

.35 |

.20 |

.15 |

|

237 |

237 |

.35 |

.20 |

.15 |

|

238 |

238 |

.35 |

.20 |

.15 |

|

239 |

239 |

.35 |

.20 |

.15 |

|

240 |

1 |

.20 |

.20 |

.15 |

|

241 |

1 |

.35 |

.25 |

.15 |

|

242 |

1 |

.50 |

.35 |

.15 |

|

243 |

1 |

.70 |

.40 |

.15 |

|

244 |

71 |

.08 |

.08 |

.08 |

|

245 |

245 |

.35 |

.20 |

.15 |

|

246 |

246 |

.35 |

.20 |

.15 |

|

247 |

247 |

.35 |

.20 |

.15 |

|

248 |

248 |

.35 |

.20 |

.15 |

|

249 |

249 |

.35 |

.20 |

.15 |

|

250 |

252 |

.70 |

.40 |

.20 |

|

251 |

251 |

.35 |

.30 |

.20 |

|

252 |

252 |

.50 |

.35 |

.20 |

|

253 |

253 |

.35 |

.30 |

.30 |

|

254 |

252 |

.35 |

.30 |

.20 |

|

255* |

254 |

.35 |

.35 |

.35 |

No Screen Color Assignment Table

|

Color # |

No Screen | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

1 |

7 |

.15 |

.15 |

.15 |

|

2 |

7 |

.35 |

.20 |

.15 |

|

3 |

7 |

.50 |

.30 |

.15 |

|

4 |

7 |

.70 |

.40 |

.15 |

|

5 |

7 |

.70 |

.40 |

.15 |

|

6 |

7 |

.50 |

.30 |

.15 |

|

7 |

7 |

.50 |

.30 |

.15 |

|

8 |

7 |

.15 |

.15 |

.15 |

|

9 |

7 |

.70 |

.40 |

.15 |

|

10 |

7 |

.15 |

.15 |

.15 |

|

11 |

7 |

.35 |

.20 |

.15 |

|

12 |

7 |

.15 |

.15 |

.15 |

|

13 |

7 |

.35 |

.20 |

.15 |

|

14 |

7 |

.35 |

.20 |

.15 |

|

15 |

7 |

.35 |

.20 |

.15 |

|

16 |

16 |

.35 |

.20 |

.15 |

|

17 |

17 |

.35 |

.20 |

.15 |

|

18 |

18 |

.35 |

.20 |

.15 |

|

19 |

19 |

.35 |

.20 |

.15 |

|

20 |

23 |

.25 |

.25 |

.20 |

|

21 |

71 |

1.0 .50 .15 | ||

|

22 |

23 |

.50 |

.35 |

.20 |

|

23 |

23 |

.70 |

.40 |

.20 |

|

24 |

23 |

.35 |

.25 |

.20 |

|

25 |

25 |

.35 |

.25 |

.20 |

|

26 |

26 |

.35 |

.25 |

.20 |

|

27 |

27 |

.35 |

.25 |

.20 |

|

28 |

28 |

.35 |

.25 |

.20 |

|

29 |

29 |

.35 |

.25 |

.20 |

|

30 |

71 |

.15 |

.15 |

.15 |

|

31 |

30 |

.35 |

.25 |

.15 |

|

32 |

30 |

.50 |

.35 |

.15 |

|

33 |

30 |

.70 |

.40 |

.15 |

|

34 |

30 |

.20 |

.20 |

.15 |

|

35 |

35 |

.35 |

.20 |

.15 |

|

36 |

36 |

.35 |

.20 |

.15 |

|

37 |

37 |

.35 |

.20 |

.15 |

|

38 |

38 |

.35 |

.20 |

.15 |

|

39 |

39 |

.35 |

.20 |

.15 |

|

40 |

40 |

.25 |

.25 |

.20 |

|

41 |

71 |

.15 |

.15 |

.15 |

|

42 |

40 |

.50 |

.35 |

.20 |

|

43 |

40 |

.70 |

.40 |

.20 |

|

44 |

40 |

.35 |

.25 |

.20 |

|

45 |

45 |

.35 |

.25 |

.20 |

|

46 |

46 |

.35 |

.25 |

.20 |

|

47 |

47 |

.35 |

.25 |

.20 |

|

48 |

48 |

.35 |

.25 |

.20 |

|

49 |

49 |

.35 |

.25 |

.20 |

|

50 |

2 |

.25 |

.25 |

.20 |

|

51 |

2 |

.35 |

.25 |

.20 |

|

52 |

2 |

.50 |

.35 |

.20 |

|

53 |

■SK3 |

.40 |

.15 | |

|

54 |

2 |

.70 |

.40 |

.20 |

|

55 |

251 |

.30 |

.20 |

.20 |

|

56 |

56 |

.35 |

.25 |

.20 |

|

57 |

57 |

.35 |

.25 |

.20 |

|

58 |

58 |

.35 |

.25 |

.20 |

|

59 |

59 |

.35 |

.25 |

.20 |

|

60 |

60 |

.25 |

.25 |

.20 |

|

61 |

60 |

.35 |

.25 |

.20 |

|

62 |

60 |

.50 |

.35 |

.20 |

|

63 |

60 |

.70 |

.40 |

.20 |

|

64 |

64 |

.35 |

.25 |

.20 |

|

Color # |

No Screen | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

65 |

65 |

.35 |

.25 |

.20 |

|

66 |

66 |

.35 |

.25 |

.20 |

|

67 |

67 |

.35 |

.25 |

.20 |

|

68 |

68 |

.35 |

.25 |

.20 |

|

69 |

69 |

.35 |

.25 |

.20 |

|

70 |

71 |

.25 |

.25 |

.20 |

|

71 |

71 |

.35 |

.25 |

.20 |

|

72 |

71 |

.50 |

.35 |

.20 |

|

73 |

71 |

.70 |

.40 |

.20 |

|

74 |

74 |

.35 |

.25 |

.20 |

|

75 |

75 |

.35 |

.25 |

.20 |

|

76 |

76 |

.35 |

.25 |

.20 |

|

77 |

77 |

.35 |

.25 |

.20 |

|

78 |

78 |

.35 |

.25 |

.20 |

|

79 |

79 |

.35 |

.25 |

.20 |

|

80 |

80 |

.20 |

.15 |

.15 |

|

81 |

80 |

.35 |

.25 |

.15 |

|

82 |

80 |

.50 |

.35 |

.15 |

|

83 |

80 |

.70 |

.40 |

.15 |

|

84 |

7 |

.35 |

.20 | |

|

85 |

7 |

.12 .12 .12 | ||

|

86 |

86 |

.35 |

.20 |

.15 |

|

87 |

87 |

.35 |

.20 |

.15 |

|

88 |

88 |

.35 |

.20 |

.15 |

|

89 |

89 |

.35 |

.20 |

.15 |

|

90 |

3 |

.20 |

.20 |

.15 |

|

91 |

3 |

.35 |

.25 |

.15 |

|

92 |

3 |

.50 |

.35 |

.15 |

|

93 |

3 |

.70 |

.40 |

.15 |

|

94 |

94 |

.35 |

.20 |

.15 |

|

95 |

95 |

.35 |

.20 |

.15 |

|

96 |

96 |

.35 |

.20 |

.15 |

|

97 |

97 |

.35 |

.20 |

.15 |

|

98 |

98 |

.35 |

.20 |

.15 |

|

99 |

99 |

.35 |

.20 |

.15 |

|

100 |

93 |

.25 |

.25 |

.20 |

|

101 |

71 |

.15 |

.15 |

.15 |

|

102 |

93 |

.50 |

.35 |

.20 |

|

103 |

93 |

.70 |

.40 |

.20 |

|

104 |

93 |

.35 |

.25 |

.20 |

|

105 |

105 |

.35 |

.25 |

.20 |

|

106 |

106 |

.35 |

.25 |

.20 |

|

107 |

107 |

.35 |

.25 |

.20 |

|

108 |

108 |

.35 |

.25 |

.20 |

|

109 |

109 |

.35 |

.25 |

.20 |

|

110 |

110 |

.20 |

.20 |

.15 |

|

111 |

110 |

.35 |

.25 |

.15 |

|

112 |

110 |

.50 |

.35 |

.15 |

|

113 |

252 |

.25 |

.20 |

.20 |

|

114 |

110 |

.70 |

.40 |

.15 |

|

115 |

115 |

.35 |

.20 |

.15 |

|

116 |

116 |

.35 |

.20 |

.15 |

|

117 |

117 |

.35 |

.20 |

.15 |

|

118 |

118 |

.35 |

.20 |

.15 |

|

119 |

119 |

.35 |

.20 |

.15 |

|

120 |

120 |

.20 |

.20 |

.15 |

|

121 |

120 |

.35 |

.25 |

.15 |

|

122 |

120 |

.50 |

.35 |

.15 |

|

123 |

120 |

.70 |

.40 |

.15 |

|

124 |

124 |

.35 |

.20 |

.15 |

|

125 |

125 |

.35 |

.20 |

.15 |

|

126 |

126 |

.35 |

.20 |

.15 |

|

127 |

127 |

.35 |

.20 |

.15 |

|

128 |

128 |

.35 |

.20 |

.15 |

|

Color # |

No Screen | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

129 |

129 |

.35 |

.20 |

.15 |

|

130 |

4 |

.20 |

.20 |

.15 |

|

131 |

4 |

.35 |

.25 |

.15 |

|

132 |

4 |

.50 |

.35 |

.15 |

|

133 |

4 |

.70 |

.40 |

.15 |

|

134 |

134 |

.35 |

.20 |

.15 |

|

135 |

252 |

.40 |

.25 |

.20 |

|

136 |

136 |

.35 |

.20 |

.15 |

|

137 |

137 |

.35 |

.20 |

.15 |

|

138 |

138 |

.35 |

.20 |

.15 |

|

139 |

139 |

.35 |

.20 |

.15 |

|

140 |

71 |

.15 |

.15 |

.15 |

|

141 |

140 |

.35 |

.25 |

.15 |

|

142 |

140 |

.50 |

.35 |

.15 |

|

143 |

140 |

.70 |

.40 |

.15 |

|

144 |

144 |

.35 |

.20 |

.15 |

|

145 |

140 |

.20 |

.20 |

.15 |

|

146 |

146 |

.35 |

.20 |

.15 |

|

147 |

147 |

.35 |

.20 |

.15 |

|

148 |

148 |

.35 |

.20 |

.15 |

|

149 |

149 |

.35 |

.20 |

.15 |

|

150 |

71 |

.15 |

.15 |

.15 |

|

151 |

150 |

.35 |

.25 |

.15 |

|

152 |

150 |

.50 |

.35 |

.15 |

|

153 |

150 |

.70 |

.40 |

.15 |

|

154 |

150 |

.20 |

.20 |

.15 |

|

155 |

155 |

.35 |

.20 |

.15 |

|

156 |

156 |

.35 |

.20 |

.15 |

|

157 |

157 |

.35 |

.20 |

.15 |

|

158 |

158 |

.35 |

.20 |

.15 |

|

159 |

159 |

.35 |

.20 |

.15 |

|

160 |

160 |

.20 |

.20 |

.15 |

|

161 |

160 |

.35 |

.25 |

.15 |

|

162 |

160 |

.50 |

.35 |

.15 |

|

163 |

160 |

.70 |

.40 |

.15 |

|

164 |

164 |

.35 |

.20 |

.15 |

|

165 |

.15 |

.15 | ||

|

166 |

166 |

.35 |

.20 |

.15 |

|

167 |

167 |

.35 |

.20 |

.15 |

|

168 |

168 |

.35 |

.20 |

.15 |

|

169 |

169 |

.35 |

.20 |

.15 |

|

170 |

5 |

.20 |

.20 |

.15 |

|

171 |

71 |

.35 .20 .15 | ||

|

172 |

5 |

.50 |

.35 |

.15 |

|

173 |

5 |

.70 |

.40 |

.15 |

|

174 |

174 |

.35 |

.20 |

.15 |

|

175 |

5 |

.35 |

.25 |

.15 |

|

176 |

176 |

.35 |

.20 |

.15 |

|

177 |

177 |

.35 |

.20 |

.15 |

|

178 |

178 |

.35 |

.20 |

.15 |

|

179 |

179 |

.35 |

.20 |

.15 |

|

180 |

182 |

.20 |

.20 |

.15 |

|

181 |

182 |

.35 |

.25 |

.15 |

|

182 |

182 |

.50 |

.35 |

.15 |

|

183 |

182 |

.70 |

.40 |

.15 |

|

184 |

184 |

.35 |

.20 |

.15 |

|

185 |

71 |

.05 .05 .05 | ||

|

186 |

186 |

.35 |

.20 |

.15 |

|

187 |

187 |

.35 |

.20 |

.15 |

|

188 |

188 |

.35 |

.20 |

.15 |

|

189 |

189 |

.35 |

.20 |

.15 |

|

190 |

190 |

.20 |

.20 |

.15 |

|

191 |

190 |

.35 |

.25 |

.15 |

|

192 |

190 |

.50 |

.35 |

.15 |

|

Color # |

No Screen | |||

|

Pen # |

Plot Type | |||

|

R |

H |

0 | ||

|

193 |

190 |

.70 |

.40 |

.15 |

|

194 |

194 |

.35 |

.20 |

.15 |

|

195 |

195 |

.35 |

.20 |

.15 |

|

196 |

196 |

.35 |

.20 |

.15 |

|

197 |

197 |

.35 |

.20 |

.15 |

|

198 |

198 |

.35 |

.20 |

.15 |

|

199 |

199 |

.35 |

.20 |

.15 |

|

200 |

200 |

.20 |

.20 |

.15 |

|

201 |

200 |

.35 |

.25 |

.15 |

|

202 |

200 |

.50 |

.35 |

.15 |

|

203 |

200 |

.70 |

.40 |

.15 |

|

204 |

204 |

.35 |

.20 |

.15 |

|

205 |

.35 |

1.0 |

.15 | |

|

206 |

206 |

.35 |

.20 |

.15 |

|

207 |

207 |

.35 |

.20 |

.15 |

|

208 |

208 |

.35 |

.20 |

.15 |

|

209 |

209 |

.35 |

.20 |

.15 |

|

210 |

6 |

.20 |

.20 |

.15 |

|

211 |

6 |

.35 |

.25 |

.15 |

|

212 |

6 |

.50 |

.35 |

.15 |

|

213 |

6 |

.70 |

.40 |

.15 |

|

214 |

214 |

.35 |

.20 |

.15 |

|

215 |

215 |

.35 |

.20 |

.15 |

|

216 |

216 |

.35 |

.20 |

.15 |

|

217 |

217 |

.35 |

.20 |

.15 |

|

218 |

218 |

.35 |

.20 |

.15 |

|

219 |

219 |

.35 |

.20 |

.15 |

|

220 |

220 |

.20 |

.20 |

.15 |

|

221 |

.35 |

.20 |

.15 | |

|

222 |

220 |

.50 |

.35 |

.15 |

|

223 |

220 |

.70 |

.40 |

.15 |

|

224 |

224 |

.35 |

.20 |

.15 |

|

225 |

220 |

.35 |

.25 |

.15 |

|

226 |

226 |

.35 |

.20 |

.15 |

|

227 |

227 |

.35 |

.20 |

.15 |

|

228 |

228 |

.35 |

.20 |

.15 |

|

229 |

229 |

.35 |

.20 |

.15 |

|

230 |

230 |

.20 |

.20 |

.15 |

|

231 |

230 |

.35 |

.25 |

.15 |

|

232 |

230 |

.50 |

.35 |

.15 |

|

233 |

230 |

.70 |

.40 |

.15 |

|

234 |

234 |

.35 |

.20 |

.15 |

|

235 |

235 |

.35 |

.20 |

.15 |

|

236 |

236 |

.35 |

.20 |

.15 |

|

237 |

237 |

.35 |

.20 |

.15 |

|

238 |

238 |

.35 |

.20 |

.15 |

|

239 |

239 |

.35 |

.20 |

.15 |

|

240 |

1 |

.20 |

.20 |

.15 |

|

241 |

1 |

.35 |

.25 |

.15 |

|

242 |

1 |

.50 |

.35 |

.15 |

|

243 |

1 |

.70 |

.40 |

.15 |

|

244 |

71 |

.08 |

.08 |

.08 |

|

245 |

245 |

.35 |

.20 |

.15 |

|

246 |

246 |

.35 |

.20 |

.15 |

|

247 |

247 |

.35 |

.20 |

.15 |

|

248 |

248 |

.35 |

.20 |

.15 |

|

249 |

249 |

.35 |

.20 |

.15 |

|

250 |

252 |

.70 |

.40 |

.20 |

|

251 |

251 |

.35 |

.30 |

.20 |

|

252 |

252 |

.50 |

.30 |

.20 |

|

253 |

253 |

.35 |

.30 |

.30 |

|

254 |

7 |

.35 |

.20 |

.15 |

|

255* |

254 |

.35 |

.35 |

.35 | |

Architectural Layer Assignments

|

LAYER |

TYPE OF INFORMATION |

COLOR Default BOLD Color By Layer |

PLOTTED LINE WIDTH |

DTS* |

Default LINE TYPE |

|

Base Layer | |||||

|

SCREENED | |||||

|

100 |

Project Title, North Arrow |

6, 221 |

50 mm |

M |

Continuous |

|

101 |

Section and Elevation Symbols, Reference Box, Detail Title |

6, 53, 221 |

.35 mm |

M |

Continuous |

|

102 |

General Notes, Symbol Legends |

6, 221 |

.35 mm |

S |

Continuous |

|

103/183 |

Alternate Dimension Text on Standard Details |

30, 221 |

.35 mm |

S |

Continuous |

|

104 |

Text (not covered by other layers), Revision Triangles, Key Notes, Leader Lines |

221 |

.35 mm |

S |

Continuous |

|

105 |

Room Names, Area Designations |

6 |

.50 mm |

M |

Continuous |

|

106 |

Room Numbers |

221 |

.35 mm |

S |

Continuous |

|

107 108 |

Square Footage (or metric equivalent), Area Calculations Unassigned |

221 |

.35 mm |

S |

Continuous |

|

109 |

Hatching |

140 |

.15 mm |

M |

Continuous |

|

110 |

Details, Elevations, Sections, Schedules |

1, 171, 3, 53 |

.35 mm |

M |

Continuous |

|

111 |

Demolition |

171 |

.35 mm |

M |

Dashed |

|

112 |

Dimensions (other than Base) |

30, 221 |

.15 mm |

S |

Continuous |

|

113 |

Base Dimensions |

30, 221 |

.15 mm |

S |

Continuous |

|

114 |

Column Grid Dimensions (do not use extension lines) |

30, 221 |

.15 mm |

S |

Continuous |

|

115 |

Column Grid |

1 |

.15 mm |

S |

Center |

|

116 |

Column Bubbles |

6, 221 |

.35 mm |

S |

Continuous |

|

117 |

Reflected Ceiling Grid |

140 |

.15 mm |

S |

Continuous |

|

118 |

Reflected Ceiling Door Segments |

254 |

.35 mm |

S |

Continuous |

|

118-T |

Reflected Ceiling Door Segments in Structural Walls/Layer 121 |

254 |

.35 mm |

S |

Continuous |

|

118-N |

Reflected Ceiling Door Segments in Non-Structural Walls/Layer 122 |

254 |

.35 mm |

S |

Continuous |

|

119 |

Match Lines |

53 |

.70 mm |

S |

Continuous |

|

120 |

Structural Walls (other than precast panels) |

7 |

.50 mm |

S |

Continuous |

|

121 |

Precast Panels, Shear Walls |

7 |

.50 mm |

S |

Continuous |

|

122 |

Non-Structural Walls (other than precast panels) |

254 |

.35 mm |

S |

Continuous |

|

123 |

Wall Finishes |

171 |

.35 mm |

S |

Continuous |

|

124 |

Core Areas, Elevators, Stairs |

8 |

.50 mm |

S |

Continuous |

|

125 |

Doors |

254 |

.35 mm |

S |

Continuous |

|

126 |

Door Symbols |

84 |

.35 mm |

S |

Continuous |

|

127 |

Windows in Structural Walls/Layers 120 and 121 |

254 |

.35 mm |

S |

Continuous |

|

127-N |

Windows in Non-Structural Walls/Layer 122 |

254 |

.35 mm |

S |

Continuous |

|

128 |

Window Symbols |

84 |

.35 mm |

S |

Continuous |

|

129 |

Plumbing Fixtures |

8 |

.15 mm |

S |

Continuous |

|

130 |

Non-Base Miscellaneous (such as closet shelves) |

8, 254 |

.15 mm |

S |

Continuous |

|

131 |

Base Miscellaneous, Permanent Furniture (such as lobby desks, etc.) |

8, 254 |

.15 mm |

S |

Continuous |

|

132 |

Roof |

8, 254 |

.15 mm |

S |

Continuous |

|

133 |

Fixed Bathroom Partitions, Countertops |

8 |

.15 mm |

S |

Continuous |

|

134 |

Kitchen Appliances, Laundry Equipment |

8 |

.15 mm |

S |

Continuous |

|

135 |

Existing Conditions |

252, 253 |

.50 mm |

S |

Continuous |

|

136 |

Paving/Site Work |

2, 30 |

.35 mm |

S |

Continuous |

|

137 |

Schematic - Vehicles, Foliage, People |

3, 84 |

.50 mm |

S |

Continuous |

|

138 |

Movable Interior Partitions |

8 |

.15 mm |

S |

Continuous |

|

139 |

Movable Interior Furniture |

140 |

.15 mm |

S |

Continuous |

|

140 |

Multi-Layer Block Insertion |

1 |

.15 mm |

S |

Continuous |

|

141 |

Basesheet Name and Date |

1 |

.15 mm |

S |

Continuous |

|

142 |

Wall Symbol |

84 |

.35 mm |

S |

Continuous |

|

143 |

Panel Symbol |

84 |

.35 mm |

S |

Continuous |

|

144 |

Equipment Symbol |

84 |

.35 mm |

S |

Continuous |

|

145 |

Break Line Symbol, Special Arrow |

7, 8 |

.50 mm |

S |

Continuous |

|

146 |

Floor Penetration Borders (for chase/stair openings) |

3 |

.50 mm |

S |

Continuous |

|

LAYER |

TYPE OF INFORMATION |

COLOR Default BOLD Color By Layer |

PLOTTED LINE WIDTH |

DTS* |

Default LINE TYPE |

|

Base Layer | |||||

|

SCREENED | |||||

|

147 |

Window Sills (inserted by window program) |

254 |

.35 mm |

S |

Continuous |

|

148 |

Columns |

7 |

.50 mm |

S |

Continuous |

|

149 |

Rustication |

8 |

.15 mm |

S |

Continuous |

|

150 |

Reflected Ceiling Plan Border |

6, 221 |

.50 mm |

M |

Continuous |

|

151 |

Reflected Ceiling Plan Section and Elevation Symbols, Reference Box, Detail Title |

6, 53, 221 |

.35 mm |

S |

Continuous |

|

152 |

Reflected Ceiling Plan General Notes, Symbol Legends |

6, 221 |

.35 mm |

S |

Continuous |

|

153/163 |

Reflected Ceiling Plan Alternate Dimension Text |

30, 221 |

.35 mm |

S |

Continuous |

|

154 |

Reflected Ceiling Plan Text, Revision Triangles, Key Notes, Leader Lines |

6, 221 |

.35 mm |

S |

Continuous |

|

156 |

Reflected Ceiling Plan Details, Elevations, Sections, Schedules |

171, 1, 3, 53 |

.35 mm |

M |

Continuous |

|

157 |

Reflected Ceiling Plan Dimensions |

30, 221 |

.15 mm |

S |

Continuous |

|

158 |

Reflected Ceiling Plan Hatching |

140 |

.15 mm |

S |

Continuous |

|

159 |

Reflected Ceiling Plan Miscellaneous |

1, 221, 6, 53 |

.35 mm |

S |

Continuous |

|

160 161-199 |

Exposed Beams, Soffits, Breaks in Hard Ceiling Reserved |

1 |

.15 mm |

S |

Continuous |

|

1-clip |

Clip Borders, Names, Dates |

2 |

.35 mm |

M |

Continuous |

*DTS = Default Text Size (S = Small, M = Medium, L = Large, H = Huge)

Electrical Layer Assignments

|

LAYER |

COLOR |

PLOTTED |

DTS* |

Default | |||

|

Base |

TYPE of INFORMATION |

Default BOLD |

LINE |

LINE | |||

|

Layer |

Color By Layer |

WIDTH |

TYPE | ||||

|

SCREENED | |||||||

|

300 301 302 303/383 304 |

Project Title, North Arrow Section and Elevation Symbols, Reference Box, Detail Title General Notes, Symbols Legends Alternate Dimension Text on Standard Details Text (not covered by other layers), Revision Triangles, Key Notes |

6, 221 1, 6, 5, 3, 221 6, 221 221 6, 221 |

.50 mm .35 mm .35 mm .35 mm .35 mm |

M S S S |

Continuous Continuous Continuous Continuous Continuous | ||

|

305 306 307 308 309 |